Introduction

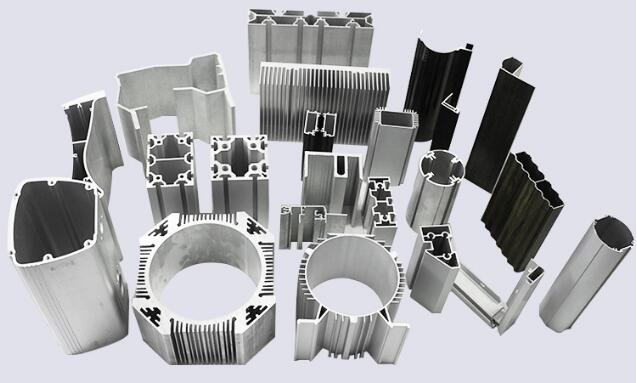

In the intricate world of aluminum profiles, ensuring impeccable mechanical properties is paramount for optimal performance. This article dives into a comprehensive analysis of the causes leading to unqualified mechanical properties and explores effective solutions to elevate the performance of aluminum profiles.

Causes of Unqualified Mechanical Properties

Low Extrusion Temperature and Slow Speed: When the extrusion temperature is too low and the speed too slow, the profile may not reach the solid solution temperature, hampering solid solution strengthening. Understanding the critical role of temperature in achieving desired mechanical properties is key.

Inadequate Cooling Conditions at Profile Exit: Insufficient air volume and slow cooling rates can lead to premature precipitation of coarse Mg2Si, impacting heat treatment and mechanical behavior. We explore the nuances of cooling conditions and their direct influence on profile quality.

Ingot Composition Non-compliance: Examining the composition of the ingot, specifically Mg and Si content, sheds light on how non-compliance with standard requirements can affect mechanical properties. The importance of adhering to composition standards is emphasized.

Lack of Ingot Homogenization: Non-homogenized ingots can hinder solid solution during extrusion, affecting the overall performance of the profile. We delve into the significance of ingot homogenization for improved mechanical properties.

Issues with Aging Process: From improper aging processes to poor hot air circulation and thermocouple installation, we uncover how these factors can lead to insufficient or over-aging, impacting the mechanical properties of aluminum profiles.

Solutions to Improve Mechanical Properties

Control Extrusion Temperature and Speed: Implementing measures to control extrusion temperature and speed ensures that the exit temperature remains above the minimum solid solution temperature, enhancing mechanical properties.

Enhance Air Cooling Conditions: The installation of atomization cooling devices proves instrumental in achieving the necessary cooling gradient for 6063 alloy profiles.

Strengthen Quality Management of Ingots: Ensuring ingot composition meets standard requirements is crucial for maintaining high-quality mechanical properties.

Implement Ingot Homogenization: Homogenizing ingots is a key step to facilitate solid solution during extrusion, contributing to improved mechanical performance.

Optimize Aging Process: Properly determining aging processes, correct thermocouple installation, and ensuring smooth hot air circulation are essential for preventing issues related to aging and maintaining desired mechanical properties.

Conclusion

Understanding the causes of unqualified mechanical properties and implementing effective solutions is pivotal in unlocking the full potential of aluminum profiles. By addressing these factors, manufacturers can ensure a consistent and high level of mechanical performance, meeting the diverse needs of various applications.