Introduction

The automobile industry is undergoing a significant transformation, thanks to the increasing use of aluminum profiles. Renowned for its lightweight yet strong properties, aluminum is redefining automotive manufacturing.

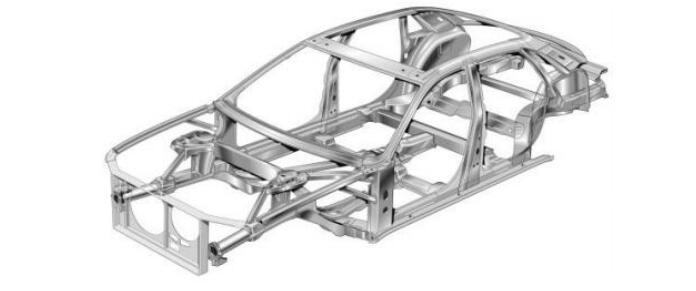

Aluminum in Automobile Body Structure

Aluminum profiles are integral in creating lighter vehicle bodies. This reduction in weight leads to improved fuel economy and enhanced driving performance. Beyond weight savings, aluminum offers the necessary strength and rigidity, ensuring structural support and safety during collisions.

Aluminum Profiles in Engine Components

Engine components such as cylinder heads and intake manifolds are increasingly being made from aluminum profiles. This material’s excellent thermal conductivity and resistance to high temperatures not only reduce the engine’s weight but also improve heat dissipation, leading to greater engine efficiency.

Advancements in Suspension Systems with Aluminum

In suspension systems, aluminum profiles play a critical role. Components like suspension tubes and shock absorber brackets benefit from aluminum’s lightweight nature, leading to a reduction in overall suspension system weight, thus enhancing performance and stability.

Elevating Car Interiors with Aluminum

The use of aluminum in car interiors, such as in door handles and center control panels, adds a touch of modernity and luxury. Aluminum’s excellent surface treatment properties allow for a sophisticated and high-end interior aesthetic.

Conclusion

The application of aluminum profiles in automobiles is bringing numerous advantages, from lightweight design and high strength to improved thermal conductivity. It is an indispensable material in the modern automobile industry, meeting the evolving material performance requirements of contemporary vehicles.