In the versatile realm of aluminum applications, profiles stand out as a fundamental component across a wide array of industries. The 6063 grade aluminum profile, in particular, serves as a backbone for both industrial and construction applications, offering a blend of strength, ductility, and aesthetics. While at first glance, these profiles may seem interchangeable, a closer look reveals critical differences and important similarities that define their optimal use.

Common Grounds

At the core, industrial and construction aluminum profiles share the same genetic makeup. Both are crafted from 6063 grade aluminum, renowned for its excellent mechanical properties. This shared alloy composition ensures that both types of profiles offer commendable weldability, electrical and thermal conductivity, surface treatment performance, corrosion resistance, and cutting performance. These shared traits make them versatile materials suitable for a broad spectrum of applications.

Diverging Paths

Despite their commonalities, industrial and construction aluminum profiles are designed with different end uses in mind, which is reflected in their distinct characteristics.

Cross-Sectional Shapes

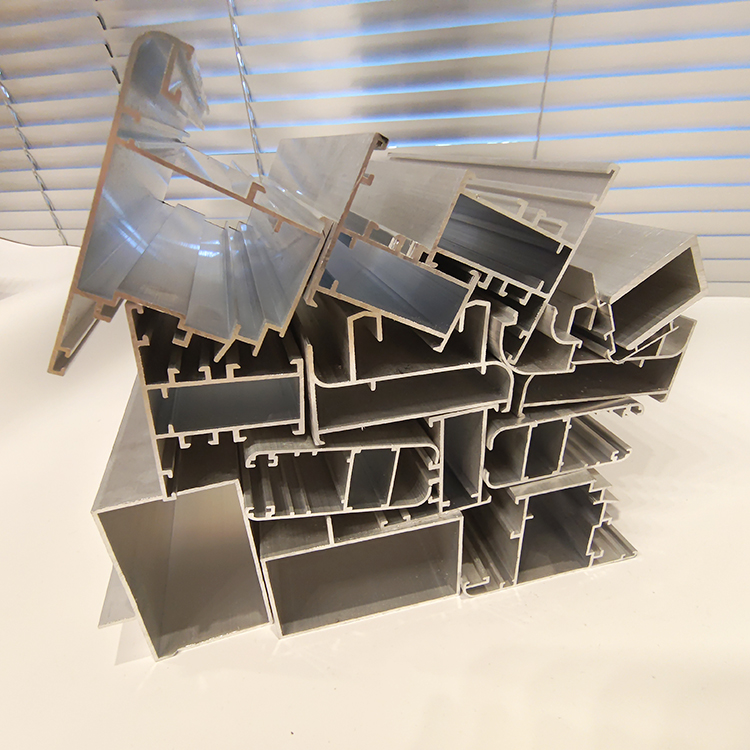

Industrial profiles tend to favor symmetry and squareness, facilitating their use in machinery and structural applications where uniformity is key. In contrast, construction profiles often feature asymmetric shapes and greater curvatures, tailored to the aesthetic and functional demands of architectural applications.

Wall Thickness

The demand for strength varies significantly between industrial and construction uses. Industrial aluminum profiles boast thicker walls to support the high load-bearing requirements of equipment frames and brackets. Conversely, construction profiles, serving more decorative roles in doors, windows, and curtain walls, can afford to have thinner walls.

Surface Treatments

When it comes to finishing touches, industrial profiles typically undergo anodizing or sandblasting to achieve a matte effect and ensure durability. Construction profiles, however, embrace a wider array of surface treatments like spraying, electrophoresis, and wood grain transfer to cater to decorative needs and offer richer color options.

Quality Requirements

Precision and aesthetics play crucial roles in industrial applications, where the form and position tolerance, as well as the surface quality of the base material, are held to higher standards. The transparent oxide film formed by anodization makes any surface imperfections distinctly visible, demanding impeccable surface quality.

Practical Implications

Understanding these differences is vital for professionals making informed choices about aluminum profiles for their projects. Whether it’s choosing an industrial profile for its robustness and uniformity or opting for a construction profile for its aesthetic flexibility, the decision impacts both the project’s functionality and its visual appeal.

Conclusion

Industrial and construction aluminum profiles, while cut from the same alloy, are tailored for their unique paths in the world of design and manufacturing. Recognizing the nuances between them not only enhances the selection process but also highlights the versatility and adaptability of aluminum as a material. For architects, engineers, and designers, this knowledge is key to leveraging aluminum’s full potential in their projects, ensuring both structural integrity and design excellence.