Introduction

In the realm of engineering and manufacturing, industrial aluminum profiles stand as a cornerstone of innovation and efficiency. These profiles, known for their versatility and superior properties, are integral to a myriad of applications spanning various sectors. This article delves into the intricacies of their manufacturing process, explores the array of benefits they offer, and highlights their extensive applications in today’s industrial landscape.

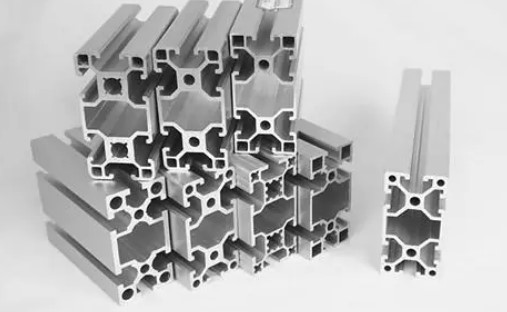

Manufacturing Process of Industrial Aluminum Profiles

The journey of an industrial aluminum profile begins with the careful preparation of aluminum rods, which are then subjected to a series of processes designed to mold them into profiles of varying shapes and sizes. The process encompasses hot melting, extrusion, cooling and straightening, surface treatment, and a rigorous quality inspection. Each step is pivotal in shaping the profile’s final characteristics, ensuring that it meets the exacting standards of durability, precision, and functionality.

Advantages of Industrial Aluminum Profiles

Aluminum profiles bring to the table a host of advantages. Their low density makes them exceptionally lightweight yet remarkably strong, catering to applications where weight reduction without compromising on strength is crucial. The material’s inherent plasticity allows for easy customization through various processing methods, facilitating the realization of complex designs. Moreover, the corrosion resistance imparted by aluminum’s oxide film and the ability to quickly assemble structures using modular connections underscore its practicality. Aesthetically, aluminum profiles can be enhanced to improve the visual appeal of the end product, making them as pleasing to the eye as they are functional.

Challenges and Limitations

Despite their numerous benefits, industrial aluminum profiles come with their set of challenges. The cost of manufacturing and processing can be high, especially for profiles requiring intricate shapes and surface treatments. Additionally, while aluminum offers high strength, its rigidity may fall short in applications demanding extreme structural integrity. The material’s susceptibility to deformation and limited temperature resistance are also considerations that necessitate careful planning and design.

Processing Methods and Customization

The adaptability of aluminum profiles is evident in the processing methods employed to tailor them to specific needs. Cutting, drilling, tapping, and finishing techniques allow for a high degree of customization, enabling designers and engineers to achieve precision and functionality. These processes are essential for creating components that fit seamlessly into larger assemblies, enhancing both the aesthetic and performance of the final product.

Applications Across Industries

The applications of industrial aluminum profiles are as diverse as they are impressive. From the backbone of machinery in manufacturing plants to the intricate components of automation equipment, aluminum profiles play a pivotal role. Their use in the transportation, chemical, food, and medical industries further attests to their adaptability and effectiveness in meeting a wide range of requirements.

The Future of Industrial Aluminum Profiles

As technology advances, the potential for industrial aluminum profiles continues to expand. Future developments in manufacturing and processing technologies promise even greater efficiency and sustainability, opening new avenues for application. The ongoing quest for lighter, stronger, and more environmentally friendly materials positions industrial aluminum profiles at the forefront of industrial innovation.

Conclusion

Industrial aluminum profiles embody the synergy between material science and engineering ingenuity. With their manufacturing process fine-tuned for quality, their advantages leveraged across industries, and their potential for innovation, they represent a key element in the pursuit of efficiency and sustainability in modern manufacturing. As we look to the future, the role of aluminum profiles in driving industrial progress remains undeniably significant, inviting us to explore and harness their full potential.