Follow in the footsteps of Rina, take you to know more aluminum profile products

Hey there, folks! Rina Meng here, your aluminum guru, ready to take you on a thrilling adventure through the world of aluminum profiles. Get ready to have your mind blown and your aluminum-loving heart racing. We’re about to embark on a journey that will leave you craving more aluminum knowledge. Let’s dive right in!

Now, let’s clear up a little confusion right off the bat. Aluminum profiles are often called aluminum alloy profiles, but here’s the deal: they’re not the same thing. It’s like mistaking a fluffy kitten for a fierce lion, my friends. Aluminum alloys are the raw materials, while aluminum profiles are the processed products that can be used directly. The biggest difference? It’s all about the shape, baby! Aluminum alloys are just the starting point, but aluminum profiles are where the real magic happens.

So, how do these magnificent aluminum profiles come to life? Well, my friends, it’s all thanks to three mind-blowing processes: melting and casting, extrusion, and surface treatment. Picture this: a bubbling cauldron of molten aluminum, ready to be transformed into something extraordinary. It’s like a magical potion brewing in the aluminum kingdom, my friends!

First up, we have the melting and casting process. It’s where the aluminum party gets started! We gather all the ingredients, just like master chefs creating a secret recipe. We mix them together, creating a molten aluminum mixture that’s hotter than a summer BBQ. It’s like a fiery dance party in the furnace, my friends! Then, we cast the molten aluminum into round rods through a special casting system. It’s like witnessing the birth of aluminum superheroes, right before our eyes. Talk about an epic origin story, my friends!

Next, we move on to the extrusion process. This is where the real fun begins! We design molds that give the aluminum its unique shape and size. It’s like playing with a giant aluminum Play-Doh set, my friends! The heated round rods go into an extruder, which squeezes them through the molds, transforming them into the incredible profiles we know and love. It’s like watching a shape-shifting superhero in action, my friends! And let me tell you, the possibilities are endless. From sleek and slender to bold and chunky, aluminum profiles come in all shapes and sizes to suit every need. It’s like having a whole wardrobe of aluminum fashion at our fingertips!

But we’re not done just yet! We still need to give our profiles that extra touch of pizzazz. That’s where surface treatment comes in. We want our profiles to look good and stand the test of time, after all. One popular method is anodizing, which involves creating a protective oxide layer on the surface of the profile. It’s like giving our superheroes a shiny suit of armor, my friends! This oxide layer not only enhances the profile’s corrosion resistance and wear resistance but also adds a touch of visual appeal. With different colors available, like black, bronze, golden yellow, and even stainless steel, our profiles can rock any look. It’s like they’re strutting down the runway of aluminum fashion, turning heads wherever they go!

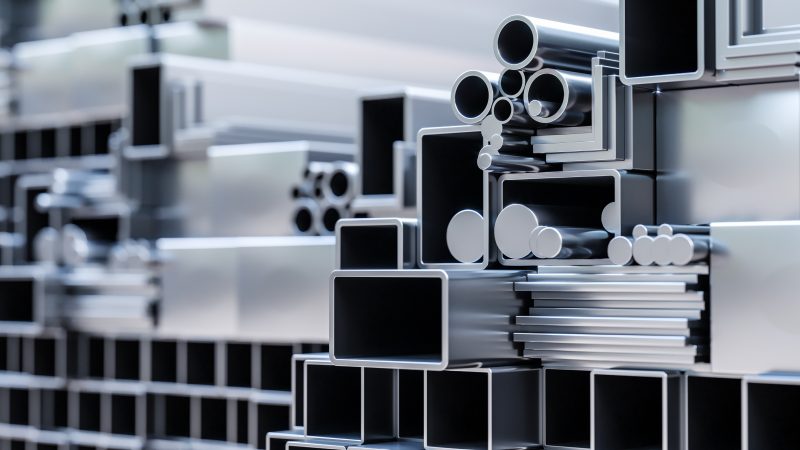

Now that we’ve unraveled the production process, let’s talk about the incredible versatility of aluminum profiles. They come in two main categories: architectural profiles and industrial profiles. Architectural profiles are the ones we encounter in our daily lives, like aluminum doors, windows, and curtain walls. They’re like the fashionistas of the aluminum world, making our homes and buildings look sleek and stylish. It’s like they’re setting the trends on the architectural runway, my friends!

On the flip side, we have industrial profiles, the unsung heroes of the aluminum family. They’re the ones that keep our industries running smoothly. From automated machinery and equipment to protective covers and customized molds, industrial profiles are the backbone of industrial production and manufacturing. It’s like they’re the superheroes behind the scenes, working tirelessly to make everything tick. Without them, our factories and production lines would be in shambles. It’s like a world without coffee—a complete disaster, my friends!

Overall, my aluminum aficionados, I hope this whirlwind tour of aluminum profiles has left you in awe of their incredible journey. From melting and casting to extrusion and surface treatment, these profiles are the unsung heroes of the aluminum world. They bring beauty, functionality, and strength to our lives, all while rocking their unique shapes and colors. So, the next time you see an aluminum door or window, take a moment to appreciate the magic behind it. Aluminum profiles are the true superheroes of our modern world.

Thanks for joining me on this aluminum adventure, my fellow metal maniacs! Until next time, keep shining bright like aluminum profiles and remember, the power of aluminum is in your hands. Stay aluminum-obsessed and keep rocking the metal world!

Overall, I had a blast sharing the aluminum profile extravaganza with you, my dear readers. Aluminum profiles may not wear capes, but they sure know how to make a statement. From their humble beginnings as molten aluminum to their stunning transformation into sleek profiles, they embody the spirit of innovation and versatility. So, the next time you see an aluminum profile, give it a nod of appreciation. It’s the unsung hero that adds strength, style, and functionality to our world. Thanks for joining me on this aluminum-filled journey, and remember, aluminum profiles are the real superheroes of the modern age. Stay aluminum-obsessed and keep rocking the metal world!