Introduction

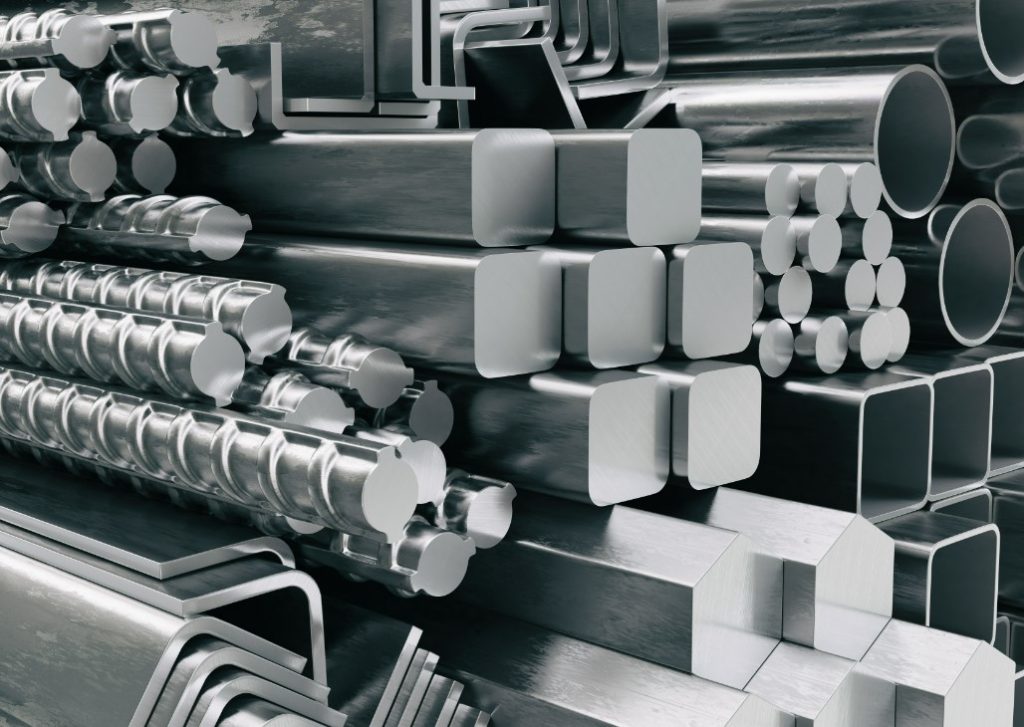

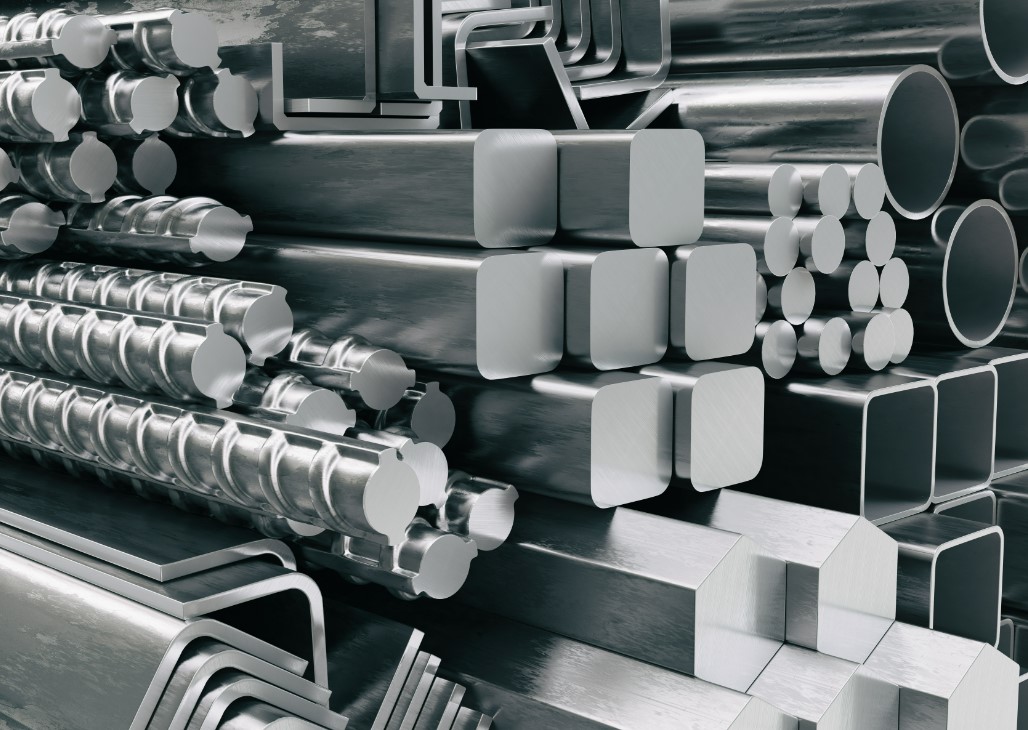

Industrial aluminum profiles are essential materials in today’s industrial landscape, widely utilized across aviation, construction, automotive, and electronics sectors. Their exceptional properties and numerous benefits have cemented their place as a vital component in various industries. This article explores the key advantages of industrial aluminum profiles and their diverse applications.

Key Advantages of Industrial Aluminum Profiles

Low Metal Density and Light Weight

One of the standout features of industrial aluminum profiles is their low metal density and light weight. These properties are particularly advantageous in the transportation and construction industries, where reducing weight without compromising strength is crucial. Lighter materials lead to increased fuel efficiency in vehicles and ease of handling in construction projects.

Strong Corrosion Resistance

Aluminum profiles exhibit strong corrosion resistance, making them ideal for applications exposed to harsh environments. This resistance ensures longevity and durability, reducing maintenance costs and extending the lifespan of products.

High Aluminum Content and Abundant Reserves

Aluminum is one of the most abundant elements on earth, and its high content in industrial profiles means that these materials are both economically viable and environmentally sustainable. The widespread availability of aluminum helps keep costs low and supports large-scale industrial usage.

Good Ductility and Strong Plasticity

The excellent ductility and plasticity of aluminum profiles provide significant advantages in manufacturing and production processes. These properties allow for easy shaping and forming, enabling the creation of complex components and structures.

Excellent Surface Treatment Performance

Aluminum profiles have superior surface treatment performance, offering both aesthetic and protective benefits. Surface treatments enhance the visual appeal of products while providing an additional layer of protection against environmental factors.

Stable Chemical Properties and Non-Magnetic Nature

The stable chemical properties and non-magnetic nature of aluminum profiles make them reliable in a variety of industrial applications. These features ensure consistent performance and compatibility with other materials and technologies.

Recyclability and Environmental Impact

Aluminum is a recyclable metal, and industrial profiles can be recycled repeatedly without losing their properties. This recyclability makes aluminum an environmentally friendly choice, contributing to sustainable development and reducing the carbon footprint.

Safety Features

Industrial aluminum profiles possess important safety features, including non-sparking properties and the absence of toxic elements. These characteristics make them suitable for use in environments where safety is paramount, such as in automotive and aerospace applications.

Applications of Industrial Aluminum Profiles

Aviation Industry

In the aviation industry, aluminum profiles are used extensively in the construction of aircraft structures and components. Their light weight and strength contribute to improved fuel efficiency and performance.

Construction Industry

The construction industry benefits greatly from aluminum profiles, which are used in building structures, facades, and various architectural elements. Their durability and aesthetic appeal make them a popular choice for modern construction projects.

Automotive Industry

Aluminum profiles are crucial in the automotive industry, where they are used in the manufacture of various auto parts. Their lightweight and non-sparking properties enhance vehicle safety and performance.

Condensers and Electronics

In the electronics sector, aluminum profiles are valued for their excellent thermal and electrical conductivity. They are commonly used in condensers and other electronic components, ensuring efficient heat dissipation and power transmission.

Challenges and Import Dependency

Despite the many advantages, some aluminum profiles still need to be imported to meet domestic production requirements. This reliance on imports can pose challenges for local industries, highlighting the need for continued development and investment in domestic aluminum production capabilities.

Conclusion

Industrial aluminum profiles offer a range of benefits, including low weight, corrosion resistance, and excellent ductility, making them indispensable across various industries. As technology and manufacturing processes continue to evolve, the use of aluminum profiles is expected to expand further, driving innovation and efficiency in industrial applications.