Introduction

Aluminum frames are essential components of photovoltaic (PV) modules, providing structural support and protection to solar panels. As global photovoltaic installations continue to grow rapidly, the demand for aluminum frames is projected to increase significantly, from around 1 million tons in 2020 to approximately 2.5 million tons in 2025. This article explores the reasons behind the color choices of aluminum frames, focusing on why they are predominantly silver and black.

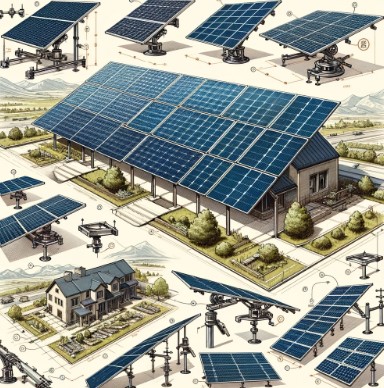

Importance of Aluminum Frames in Photovoltaics

Aluminum frames play a critical role in the performance and durability of solar panels. They are designed to support the panels, protect the edges from environmental damage, and facilitate easy mounting on various surfaces. Unlike frames used in electrical and electronic products, which can come in various colors, solar frames are typically limited to silver and black. Understanding the rationale behind this limited color palette requires examining several key factors.

Reasons for Limited Color Options

Solar panels have stringent requirements for color uniformity. The surface color of the cells must be consistent to avoid any color difference, which can affect the panel’s efficiency and appearance. Silver, being the natural color of aluminum, and black, which is less likely to show color variation, are the most suitable choices for frames. These colors ensure a uniform look that aligns with the high standards of photovoltaic modules.

Aesthetic and Functional Considerations

The aesthetics of solar panels are also a significant consideration. Solar cells are generally dark in color, with monocrystalline silicon cells being black and polycrystalline silicon cells appearing dark blue. A black frame complements the black or dark blue panels, creating a cohesive and sleek appearance. In contrast, a silver frame provides a strong, attractive contrast with the solar panel, enhancing its visual appeal. Frames in other colors often fail to achieve the same level of aesthetic integration and can appear less professional when installed on dark panels.

Cost Implications of Surface Treatments

The surface treatment of aluminum frames involves anodizing, which enhances corrosion resistance. Natural color anodizing (silver) is cost-effective because it eliminates the need for additional coloring steps. This makes silver frames the most economical option for widespread use. Black anodizing is more expensive than silver but still more affordable than other colors, making black frames a viable choice for those willing to pay a slight premium for enhanced aesthetics.

Environmental and Durability Factors

Photovoltaic power stations are typically built in large open areas or hilly terrains, where durability and corrosion resistance are more critical than aesthetic considerations. Anodized silver and black frames meet these requirements effectively, offering long-lasting protection against environmental factors. In contrast, electronic products used indoors have higher aesthetic demands due to their frequent interaction with users, necessitating a broader range of colors to appeal to consumer preferences.

Conclusion

In summary, the limited color options for aluminum frames in solar panels are driven by the need for color uniformity, aesthetic coordination, cost-effectiveness, and durability. As the demand for photovoltaic installations continues to rise, understanding these factors becomes increasingly important for stakeholders in the aluminum and solar industries. The future of aluminum frames in photovoltaics looks promising, with ongoing advancements aimed at balancing functionality, aesthetics, and cost.