Follow in the footsteps of Rina, take you to know more aluminum profile products

Hey there, fellow aluminum enthusiasts! Rina Meng here, your go-to gal for all things aluminum profiles. Today, I want to dive into the fascinating world of high-end industrial aluminum profiles. Trust me, folks, these profiles are like the superheroes of the aluminum industry—strong, versatile, and ready to save the day!

Let me start off with a personal story. Picture this: I’m strolling through a bustling city, marveling at the architectural wonders around me. Suddenly, a sleek and modern building catches my eye. Its gleaming exterior reflects the sunlight, and I can’t help but wonder what magical material was used to create such a masterpiece. Lo and behold, it’s none other than high-end industrial aluminum profiles!

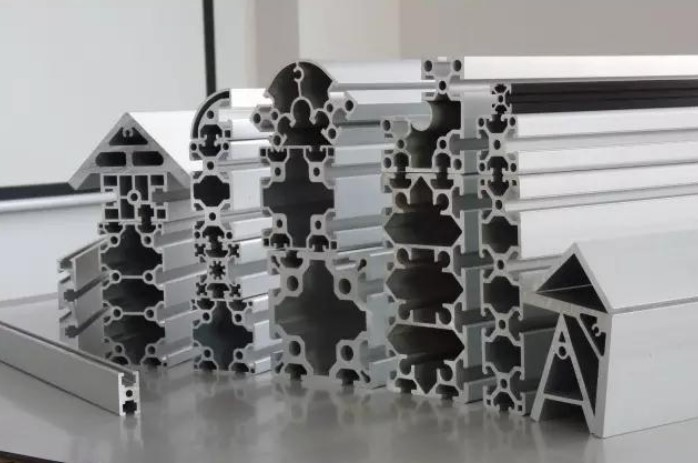

What makes these profiles so special, you ask? Well, let me break it down for you. Industrial aluminum profiles are crafted from an alloy material with aluminum as the main component. They undergo a hot-melting and extrusion process to achieve different cross-sectional shapes. But here’s the kicker—the added alloy proportion varies, leading to different applications. It’s like a secret recipe for success!

One of the standout features of these profiles is their stunning appearance. After undergoing oxidation, they boast a beautiful finish that’s resistant to dirt. And guess what? Cleaning them is a breeze! Just a simple swipe with a cloth, and they’re as good as new. Talk about low maintenance, am I right?

Now, let’s talk about their versatility. When it comes to assembling products, these profiles come in different specifications to handle various load-bearing capacities. And the best part? No welding is required! That means they’re not only environmentally friendly but also easy to install and disassemble. Plus, they’re light and portable, making them a dream to work with. Who needs heavy materials when you can have the lightweight wonder of aluminum profiles?

Compared to other metal materials, aluminum profiles have some serious advantages. They’re incredibly malleable and highly productive, making them a production powerhouse. Their ductility is off the charts, allowing them to be combined with different metal elements to create high-quality alloys. It’s like a symphony of metals coming together to create the perfect harmony!

Now, let’s delve into the exciting applications of high-end industrial aluminum profiles. Buckle up, folks, because we’re about to embark on a thrilling journey through aerospace, automotive, transportation, and even the realm of 3C electronics!

First stop: the aerospace industry. Did you know that aluminum alloy materials make up around 70% of the total weight of an aircraft’s body? That’s right, folks—these profiles are the unsung heroes of the sky! From aircraft shells and wings to propellers and seat brackets, aluminum profiles provide the high strength, toughness, and corrosion resistance needed for safe and reliable flights. They’re like the sturdy backbone of the aviation world!

Next up, we have the automotive industry. The concept of lightweight automobiles is all the rage nowadays. And you know what? Aluminum profiles are leading the charge! They help reduce the weight of vehicles without compromising performance, safety, or comfort. It’s like having your cake and eating it too! With aluminum profiles, automakers can create components like battery trays, bumpers, and sub-frames that are not only lightweight but also durable and cost-effective. It’s a win-win situation, my friends!

But wait, there’s more! Aluminum profiles are also making waves in the world of transportation. With the rapid development of urban rail systems, high-speed trains, light rail trains, and subways are becoming the lifeblood of modern cities. And guess who’s there to lend a helping hand? You got it—aluminum profiles! Their lightweight nature, excellent formability, and corrosion resistance make them the ideal choice for rail transit equipment. Whether it’s conductive rails or busbars, aluminum profiles are the unsung heroes of the railway world!

Last but not least, let’s talk about the role of aluminum profiles in the 3C electronics and communications industry. Aluminum’s lighter weight, high strength, and excellent electrical conductivity make it a top contender for manufacturing high-end electronic products. Think smartphones, laptops, and other gadgets that we can’t live without. Aluminum profiles offer better control during complex forming processes and boast mature surface treatment options like anodizing, wire drawing, and sandblasting. They’re like the secret ingredient that adds that extra oomph to our beloved electronic devices!

Overall, the application of high-end industrial aluminum profiles is nothing short of extraordinary. They’re the unsung heroes that support the marvels of modern engineering. From airplanes soaring through the sky to high-speed trains whisking us away, these profiles are the backbone of innovation and development.

So, my fellow aluminum aficionados, let’s raise a toast to the incredible world of high-end industrial aluminum profiles. They’re the real MVPs, the superheroes of the aluminum industry! Thanks for joining me on this aluminum adventure. Until next time, keep shining bright like an aluminum diamond!