Rina takes you on today’s journey together

Hey there, aluminum aficionados! Rina Meng here, ready to take you on a wild ride through the world of aluminum gussets, aluminum veneers, and aluminum-plastic composite panels. Buckle up and get ready for a rollercoaster of information!

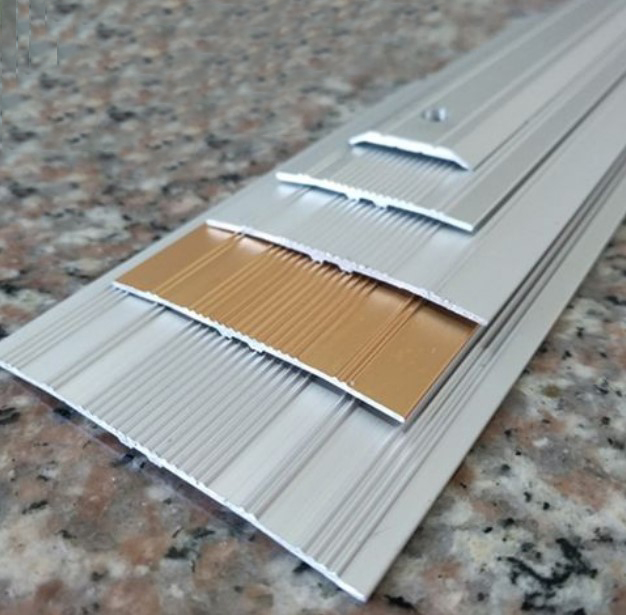

Let’s kick things off with aluminum gussets. Now, you might be wondering, what on earth are these magical gizmos? Well, my friends, aluminum gussets are those nifty little plates that come in various shapes and sizes. Picture them as the superheroes of the aluminum world, providing strength and support to structures. They’re like the Robin to Batman, the sidekick that saves the day!

But here’s the thing, it’s not all about the thickness when it comes to aluminum gussets. It’s more about the materials used. We’re talking about the elasticity, toughness, and surface treatment. You see, these gussets need to be flexible yet sturdy, like a gymnast doing a backflip on a balance beam. And let’s not forget about the surface treatment. We want those gussets to look sleek and stylish, like they just walked off the runway of an aluminum fashion show!

Now, let’s move on to aluminum veneers. These bad boys are a whole different ball game. They’re like the big brothers of the aluminum world, with a thickness of more than 1.5mm. They’re tough, resilient, and ready to take on the world. Think of them as the Hulk of the aluminum family, smashing through obstacles with ease!

Aluminum veneers are made from high-quality aluminum alloy panels, and they undergo some serious bending action through advanced CNC technology. This ensures that the panels stay flat and don’t get all wonky after processing. We want them to be as straight as an arrow, ready to withstand any external forces that come their way. And let me tell you, these veneers are no pushovers. They can handle UV radiation, oxidation, and corrosion like nobody’s business. They’re like the superheroes of durability!

Where do we use these aluminum veneers, you ask? Well, the possibilities are endless! They’re perfect for building curtain walls, columns, and beams. They make fantastic advertising signs, balconies, and partition decorations. You can even spot them in outdoor decorations, vehicles, furniture, exhibition stands, and instrument casings. They’re like the chameleons of the aluminum world, blending seamlessly into any environment!

Now, let’s switch gears and talk about aluminum-plastic composite panels. These babies are a whole different breed altogether. They’re like the hybrid cars of the aluminum world, combining the best of both worlds. Picture this: chemically treated coated aluminum panels as the surface material, and polyethylene plastic as the core material. It’s like a match made in aluminum heaven!

These composite panels are created using special aluminum-plastic panel production equipment. They’re versatile little things, with a wide range of uses. We’re talking building exterior walls, curtain wall panels, renovation of old buildings, indoor wall and ceiling decorations, advertising signs, display stands, and even purification and dust prevention projects. They’re like the Swiss Army knives of the aluminum world, ready to tackle any task you throw at them!

Now, let’s get down to the nitty-gritty. When it comes to aluminum gussets, we’ve got three grades to choose from. The first one is the aluminum-magnesium alloy, which packs a punch with its excellent oxidation resistance. It’s like the superhero of suspended ceilings, ready to save the day! Then we’ve got the aluminum-manganese alloy, which has slightly better strength and stiffness but falls a tad short in oxidation resistance. And finally, we have the aluminum alloy, which is a bit lower in strength and stiffness but still gets the job done. It’s like the underdog of the aluminum world, always ready to prove itself!

Phew! That was quite a journey through the world of aluminum gussets, aluminum veneers, and aluminum-plastic composite panels. We’ve covered the basics, explored their uses, and even dived into the different grades available. It’s a fascinating realm of possibilities, my friends!

Overall, these aluminum wonders bring strength, style, and versatility to the table. They’re like the unsung heroes of the construction industry, silently supporting structures and adding a touch of elegance. So, the next time you spot an aluminum gusset or a sleek aluminum veneer, take a moment to appreciate the craftsmanship and ingenuity behind them.

Thank you for joining me on this aluminum adventure! Remember, when it comes to gussets, veneers, and composite panels, the aluminum world is your oyster. So, go out there and embrace the aluminum revolution! Until next time, stay aluminum-tastic, my friends!