Rina takes you on today’s journey together

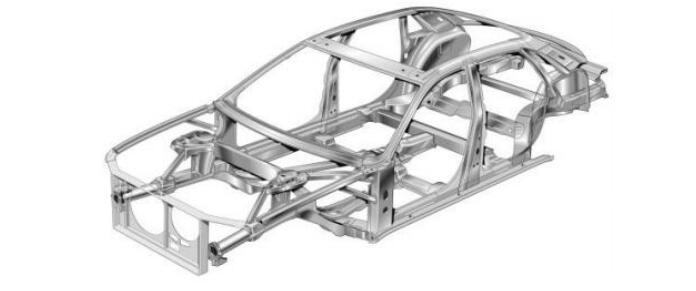

Hey there, fellow aluminum enthusiasts! Today, I want to dive into the fascinating world of anodizing automotive aluminum parts. Buckle up, because we’re about to embark on a wild ride filled with corrosion resistance, wear resistance, surface coloring, insulation, and even some paint spray action. Trust me, this is one topic you don’t want to miss!

Let me start off with a personal story. Picture this: I’m cruising down the road in my shiny aluminum-clad automobile, feeling like the coolest kid on the block. Suddenly, I notice some unsightly corrosion starting to rear its ugly head on my precious aluminum parts. Oh, the horror! That’s when I realized the importance of anodizing.

You see, automotive aluminum is a noble metal, which means it’s highly reactive and loves to buddy up with oxygen in the air to form a thin layer of alumina. Now, this alumina film is so sneaky that it becomes transparent, making it nearly impossible for the human eye to spot. Sneaky, sneaky! But here’s the kicker: this thin film of alumina acts as a shield against oxidation. It’s like having a superhero cape for your aluminum parts, protecting them from the villainous forces of corrosion.

“But Rina,” you might ask, “if the natural oxidation film does the job, why bother with anodic oxidation?” Great question, my friend! The thing is, the naturally formed oxide film can be a bit uneven, leading to darker surface colors and subpar corrosion resistance. We don’t want that, do we? No way! That’s where anodic oxidation comes to the rescue. By undergoing anodizing, we create an artificial oxide film that’s uniform in density and supercharged with corrosion-resistant powers. Talk about leveling up!

Now, let’s shift gears and talk about wear resistance. We all know that aluminum parts in cars are no strangers to scratches and wear. After all, aluminum alloys aren’t as tough as good ol’ steel. But fear not, for anodizing comes to the rescue once again! When we anodize automotive aluminum, the surface becomes as hard as nails (well, not literally, but you get the idea). The hardness of the oxide film can reach a whopping 300HV, making it incredibly resistant to wear and tear. So go ahead, take those corners a little faster without worrying about scratches. Your aluminum parts have got your back!

But wait, there’s more! Anodizing also opens up a world of possibilities when it comes to surface coloring. Before sealing the anodized parts, the surface is covered in tiny pores, just waiting to absorb some metal salts or dyes. It’s like giving your aluminum parts a makeover, complete with vibrant colors and a touch of pizzazz. Who said aluminum couldn’t be stylish?

Now, let’s talk insulation. Aluminum is a fantastic conductor of electricity, but sometimes we need it to take a break from its electric endeavors. That’s where anodizing comes into play once again. The aluminum oxide film formed during anodizing is an excellent insulator, saying “no thanks” to the flow of electric current. So, if you find yourself in a situation where insulation is key, anodizing is the way to go. It’s like giving your aluminum parts a cozy blanket to snuggle up in.

Last but not least, let’s not forget about our friends in the paint spray department. Some aluminum parts in automobiles require a little extra love in the form of painting. Luckily, anodizing has got their back too. The anodized surface of aluminum parts has a strong adsorption power, making the painting process more uniform and beautiful. It’s like providing the perfect canvas for an artistic masterpiece. Picasso would be proud!

Overall, the anodizing process for automotive aluminum parts is a game-changer. It improves corrosion resistance, enhances wear resistance, offers surface coloring options, provides insulation when needed, and even plays a role in the paint spray process. It’s like a superhero team dedicated to making your aluminum parts shine brighter than ever before.

So next time you hop into your trusty aluminum-clad vehicle, take a moment to appreciate the wonders of anodizing. It’s the secret sauce that keeps your aluminum parts looking fabulous and performing at their best. Remember, my fellow aluminum aficionados, anodizing is not just a process; it’s a way of life!

Thanks for joining me on this aluminum adventure. Until next time, keep shining bright and stay aluminum-awesome!