Rina takes you on today’s journey together

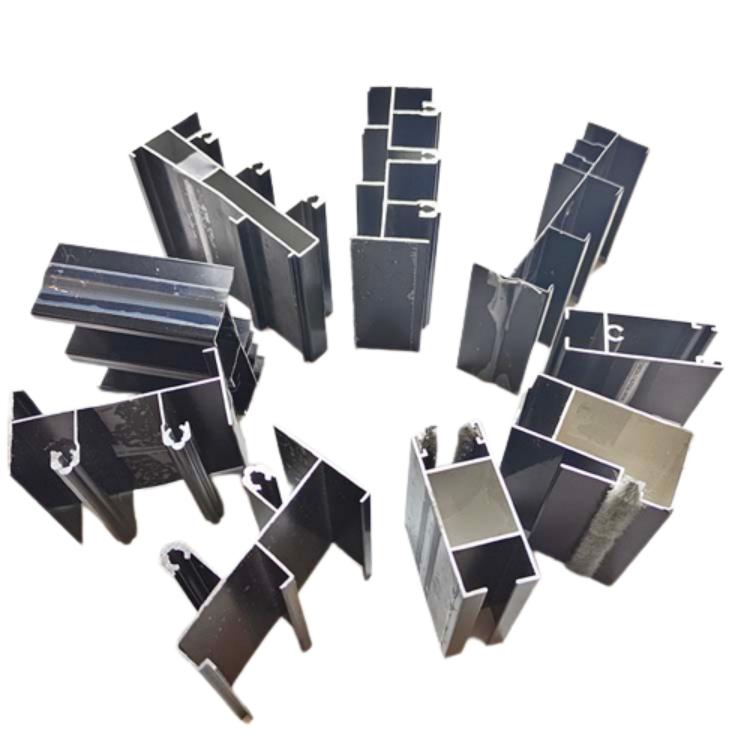

Hey there, aluminum enthusiasts! Rina Meng, the oxidation aficionado, is here to spill the beans on what happens after aluminum undergoes its magical oxidation process. You see, industrial aluminum doesn’t just strut its stuff right after being cut and shaped. It needs a little extra love and care to boost its corrosion resistance and surface hardness. So, what’s the dealio? What else needs to be done to make that aluminum shine like a star? Let’s dive in and find out!

- Anodizing Adventures: When it comes to giving aluminum that extra oomph, anodizing is the name of the game. We’ve got a few different flavors of anodizing processes, like sulfuric acid, chromic acid, oxalic acid, and phosphoric acid. But hold your horses, my friends, because sulfuric acid anodizing is the bee’s knees in the aluminum world. It’s the go-to choice for creating that dense, artificial oxide film on the surface of the aluminum. That film not only adds a touch of transparency but also amps up the hardness and durability of our beloved aluminum.

- Hot Water Hula: Once the aluminum has been through its anodizing adventure, it’s time for a little hot water lovin’. We give it a nice, warm bath to age that film layer and let it soak up all the goodness. But here’s the thing, we gotta be careful with the water temperature and washing time. Too hot or too long, and we risk thinning out the oxide film or messing with its color. We want that film to be just right, so we keep the water temperature between a toasty forty to fifty degrees Celsius and the washing time between thirty to sixty seconds. It’s all about finding that sweet spot, my friends!

- Drying Drama: After the hot water treatment, our aluminum star needs a little time to dry off. We hang it up diagonally on a shelf, letting the water flow out naturally. Why? Well, because we want that oxide film to maintain its glossy goodness, all-natural-like. No interference, no funny business. Just pure, natural drying that keeps our aluminum looking fabulous.

- Aging Antics: Now, here’s where things get interesting. The aging process can be a bit of a diva, depending on the climate. If it’s a sunny summer day, we let our aluminum bask in the glory of the sun. But if it’s rainy or winter, we pop it into the oven for a little extra TLC. The process conditions? We’re talking temperatures between a cozy forty to fifty degrees Celsius and a time span of ten to fifteen minutes. It’s like giving our aluminum a spa day, my friends. Relaxation and rejuvenation all rolled into one.

- Oxalic Acid Odyssey: Ah, oxalic acid, the wild card in the anodizing game. It’s got some unique tricks up its sleeve. You see, oxalic acid has low solubility in the aluminum oxide film, which means the film ends up with low porosity. And that low porosity brings some benefits to the table, like enhanced wear resistance and better point insulation. But here’s the catch—it comes with a price tag. Oxalic acid oxidation can cost three to five times more than sulfuric acid. Plus, it can be a bit finicky with color changes and process conditions, leading to potential color differences in the final product. So, while it has its perks, it’s not always the go-to choice.

Overall, my aluminum aficionados, the journey doesn’t end with oxidation. We’ve got anodizing adventures, hot water hula, drying drama, aging antics, and even an oxalic acid odyssey. It’s a whirlwind of treatments and processes that take our aluminum to the next level. So, the next time you gaze upon a shiny, corrosion-resistant aluminum wonder, remember the journey it went through. It’s like a transformation from a caterpillar to a butterfly, but with more metal and fewer wings!

Finally, I want to thank you for joining me on this aluminum odyssey. It’s been a wild ride, full of twists, turns, and aluminum magic. So, keep shining, my friends, and remember to embrace the beauty of aluminum and all its post-oxidation glory. Until next time, keep sparkling and stay aluminum-tastic! Catch you on the flip side!