Introduction

Aluminum, ubiquitous in modern construction, requires robust surface treatments to combat corrosion and enhance its visual appeal and longevity. This article delves into two primary methods—fluorocarbon spraying and powder coating—that elevate aluminum profiles to new heights of durability and aesthetic excellence.

Understanding Aluminum Surface Treatment

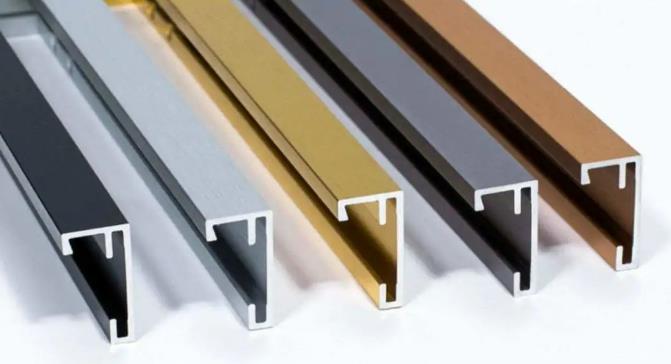

Aluminum, though versatile, is prone to corrosion when exposed to harsh environments. Surface treatment is essential to fortify its resistance and decorative qualities. Among the most effective methods are fluorocarbon spraying and powder coating, each offering distinct advantages tailored to specific applications.

Fluorocarbon Spraying: Ideal for Outdoor Profiles

Fluorocarbon spraying stands out as a premier choice for outdoor aluminum profiles due to its resilience and aesthetic benefits. This method provides uniform coloration, a metallic sheen, and exceptional resistance to fading, corrosion, and atmospheric pollutants. It finds extensive use in high-profile projects such as curtain walls, exterior panels, and decorative veneers, ensuring enduring beauty even in challenging climates.

Powder Coating: Versatility for Indoor Applications

Powder coating excels in indoor environments where aluminum profiles require durability and aesthetic flexibility. This method boasts superior UV resistance and durability indoors, making it ideal for architectural elements like curtain wall columns and beams. While not as resistant to outdoor conditions as fluorocarbon spraying, powder coating offers robust protection and customizable finishes for interior designs.

Application Considerations and Industry Trends

Choosing between fluorocarbon spraying and powder coating depends on several factors including environmental exposure, architectural intent, and maintenance expectations. The global market for advanced surface treatments in construction continues to grow, driven by demand for sustainable and visually striking building materials. Innovations in coating technologies promise further enhancements in performance and longevity for aluminum profiles.

Conclusion

Fluorocarbon spraying and powder coating represent pivotal advancements in enhancing aluminum’s functional and aesthetic attributes. Selecting the right surface treatment ensures that aluminum profiles not only endure harsh conditions but also elevate architectural designs with lasting elegance. As technology evolves, these treatments will continue to redefine standards in construction, offering unparalleled durability and visual appeal for generations to come.