Introduction

Aluminum, renowned for its versatility and strength-to-weight ratio, stands as a cornerstone in modern manufacturing across numerous industries. Central to its widespread utility is the advancement of surface treatment technologies, particularly the transformative process known as hard anodizing. This article delves into the intricacies of aluminum hard anodizing, exploring its processes, benefits, and diverse applications.

Understanding Aluminum Hard Anodizing

Aluminum hard anodizing is a specialized surface treatment that combines oxidation with dyeing to produce a robust, wear-resistant finish. Initially, the aluminum undergoes an electrochemical oxidation process, where an oxide layer forms on the metal’s surface. This layer is then dyed to achieve various colors and further enhance corrosion resistance and aesthetic appeal. The technique not only improves mechanical properties like hardness but also facilitates better adhesion for paints and adhesives.

Factors Influencing Hard Anodizing

The effectiveness of aluminum hard anodizing is intricately tied to factors such as current density during the electrochemical process. Optimal current densities promote faster oxide growth, leading to larger pore sizes in the oxide layer that facilitate dye absorption and coloration. However, excessive current density can overheat the metal surface, risking damage, while too low a density may compromise the layer’s durability. Balancing these factors is critical to achieving desired mechanical and aesthetic outcomes.

Applications of Aluminum Alloys

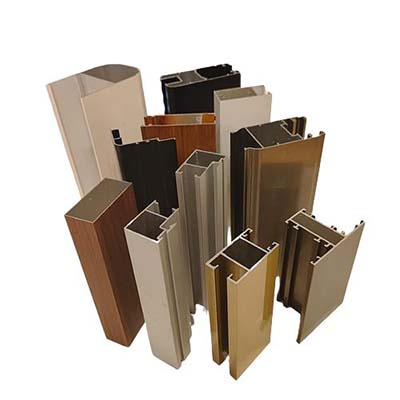

The versatility of aluminum alloys treated with hard anodizing finds application across diverse sectors. In aerospace, the enhanced durability and weight savings make it ideal for aircraft components. Automotive manufacturers utilize its corrosion resistance for engine parts and body panels. Electronics benefit from its thermal management properties, while architecture embraces its aesthetic flexibility and longevity in building facades and interior fittings.

Innovative Surface Treatment Methods

Advancements in aluminum surface treatment continue to push boundaries in sustainability and efficiency. New methodologies are emerging to reduce environmental impact and improve energy efficiency during the anodizing process. These innovations underscore a broader commitment across industries towards sustainable practices and the circular economy, aligning with global environmental goals.

Conclusion

Aluminum hard anodizing exemplifies the intersection of craftsmanship and technology, enhancing the material’s intrinsic properties for myriad applications. As industries evolve towards sustainable practices, innovations in surface treatment methods like hard anodizing play a pivotal role in meeting both performance and environmental criteria. Looking ahead, continued advancements promise further enhancements in durability, aesthetics, and ecological footprint, reinforcing aluminum’s pivotal role in the 21st-century industrial landscape.