Introduction

The quality of broken bridge aluminum window profiles plays a pivotal role in ensuring effective insulation and noise reduction in modern architecture. Understanding how to judge their quality is essential for homeowners and builders alike.

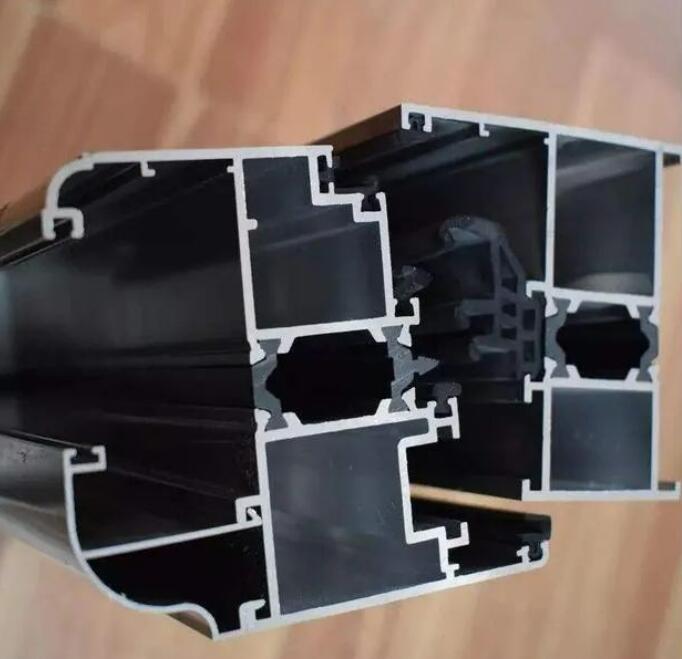

Evaluating Sealing Strips

The sealing strips in these profiles are key to their performance. The number and thickness of these strips significantly affect their thermal insulation and noise isolation capabilities. Profiles with multi-layered sealing strips, generally two or three layers, offer superior insulation compared to single-layered ones.

Connection Method of Sealing Strips

The way these sealing strips are connected within the profile is also crucial. The embedded connection method is not only common but offers greater convenience and a better sealing effect. Additionally, the presence of a drain outlet at the connection point indicates a sophisticated design that enhances the profile’s drainage and waterproofing capabilities.

Assessing Material Quality

The material’s thickness and uniformity are indicators of its quality. Thicker and uniformly distributed material in the profile suggests better material quality, leading to more reliable performance in terms of energy savings and durability.

Energy Efficiency of Broken Bridge Aluminum Profiles

These aluminum profiles are particularly effective in reducing heat conduction and preventing condensation, making them energy-efficient choices. They play a significant role in maintaining indoor temperature, thereby reducing heating costs in winter and air conditioning expenses in summer.

Airtightness and Noise Isolation

Airtightness is a critical quality parameter. The effectiveness of the embedding in the middle of the broken bridge, if tight and strong, indicates good airtightness, which is directly linked to enhanced noise isolation.

Conclusion

In conclusion, assessing the quality of broken bridge aluminum window profiles involves careful consideration of sealing strips, their connection method, material quality, and the profile’s overall airtightness. These factors are crucial for selecting high-quality profiles that ensure energy efficiency, comfort, and noise reduction in building constructions.