Introduction

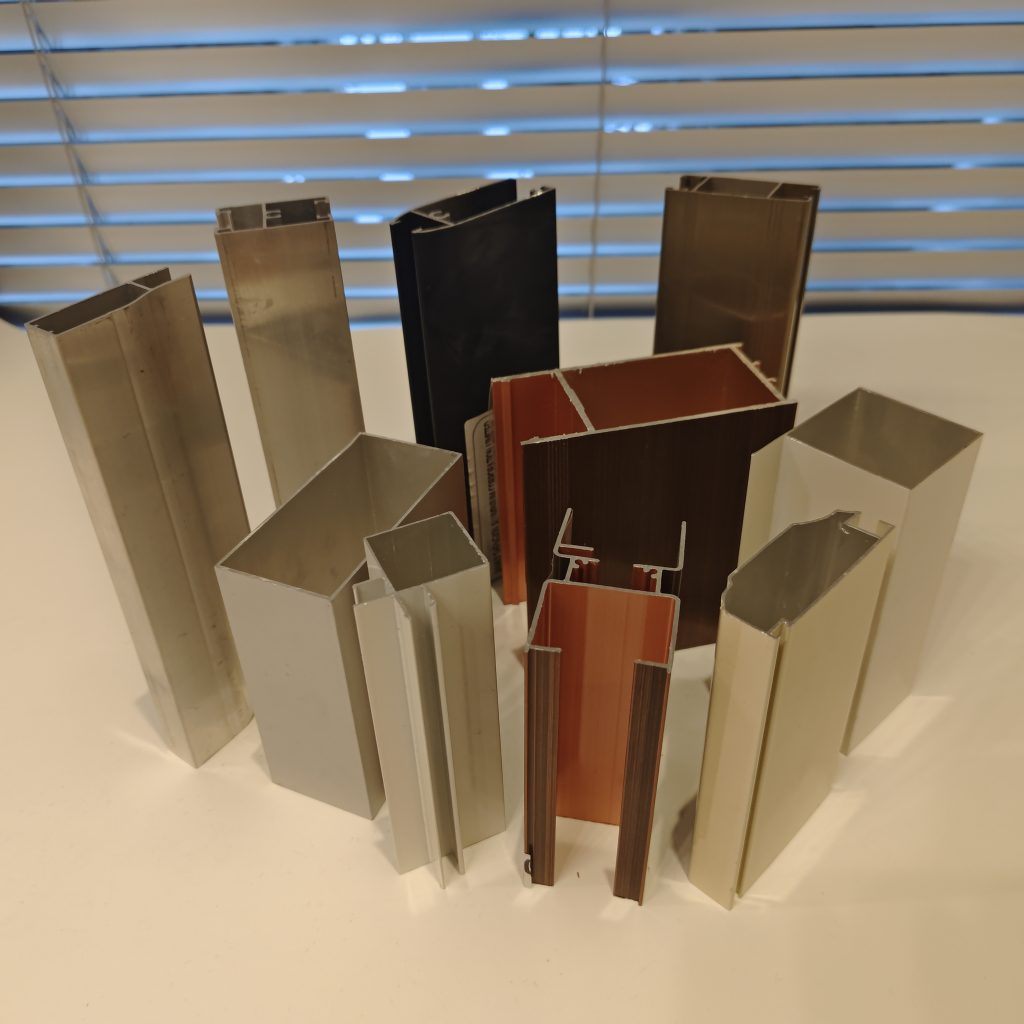

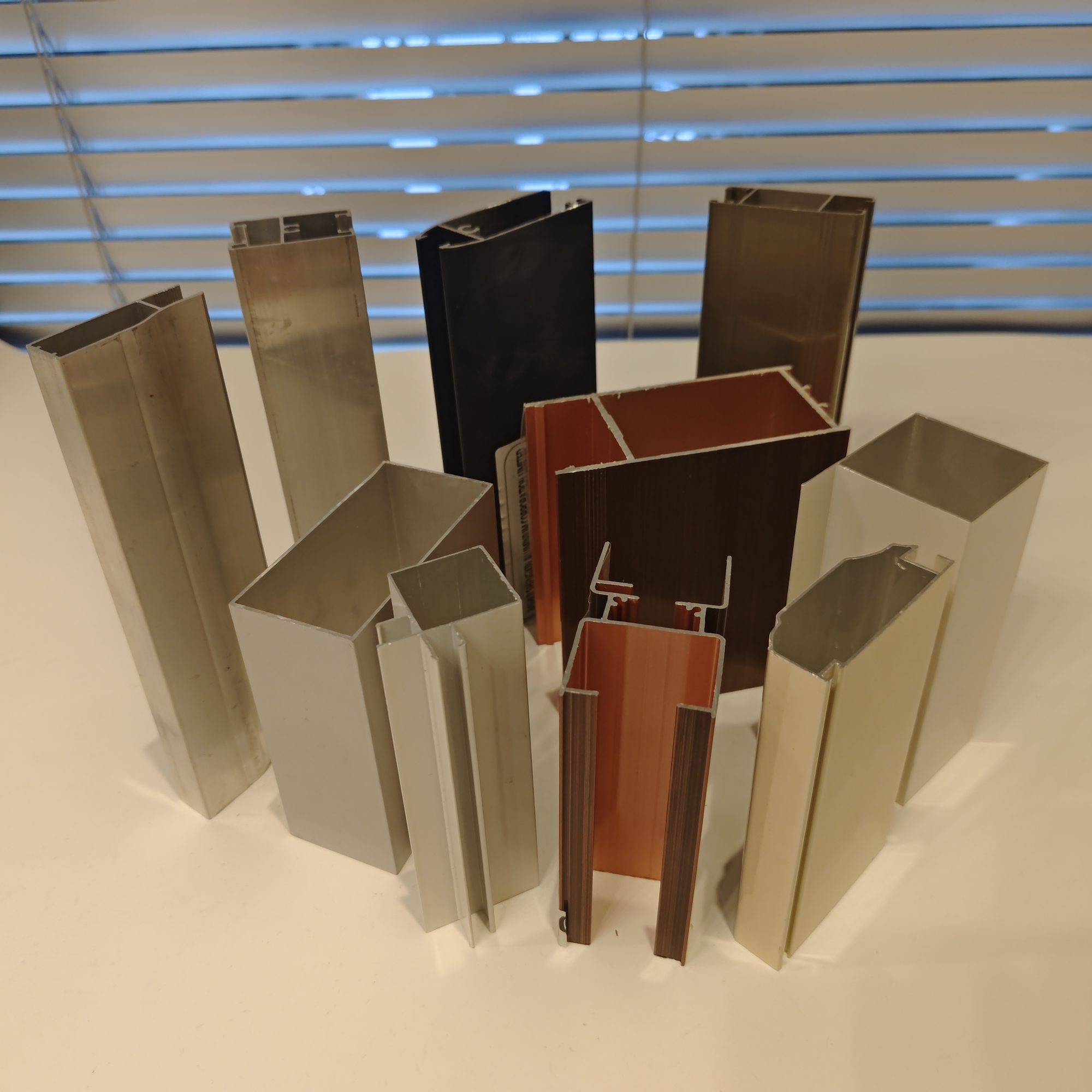

Choosing the right aluminum profiles is a critical decision for anyone involved in construction or manufacturing. The longevity and performance of doors, windows, and various structures heavily depend on the quality of the aluminum profiles used. In this guide, we’ll explore the key considerations to ensure you make informed decisions when selecting aluminum profile products.

Checking Factory Certificate

Before making any decisions, it’s essential to verify the product’s factory certificate. This document holds crucial information, including the factory date, specifications, technical conditions, company name, and production license number. A thorough examination of this certificate sets the foundation for a reliable choice.

Observing Surface Condition

The surface condition of aluminum profiles speaks volumes about their quality. A top-notch product should boast a bright color, a glossy finish, and, most importantly, a surface free from scratches, bubbles, or any defects. Careful observation at this stage is key to ensuring a visually appealing and durable end product.

Ensuring Adequate Wall Thickness

The thickness of aluminum profiles, especially in door and window materials, is a critical factor. It’s advised that the product thickness should not fall below 1.0mm. This specification ensures the structural integrity and longevity of the profiles in various applications.

Checking Surface Coating Thickness

Different types of aluminum profiles require specific surface coating thickness. Anodized products should have a film thickness not less than 10 μm, electrophoretic paint products should have a minimum of 17 μm, and powder spraying products should fall within the range of 40-120 μm. These criteria are vital for the performance and aesthetic appeal of the profiles.

Considering Corrosion Resistance

For users in coastal areas, the choice of aluminum profiles with better corrosion resistance is crucial. Options like electrophoretic painted profiles, powder sprayed profiles, or fluorocarbon sprayed profiles are recommended to withstand the corrosive effects of coastal environments.

Proper Maintenance Practices

Ensuring the longevity of aluminum profiles goes beyond the selection process. Daily maintenance is crucial. Using soft cleaning tools like cotton gauze and cloth is advised, while brushes or other hard objects should be avoided to prevent surface damage.

Cleaning Materials

While water, detergent, and soap are acceptable for cleaning, it’s essential to avoid using other organic substances. Adhering to approved cleaning materials preserves the quality and appearance of the aluminum profiles.

Conclusion

In conclusion, the meticulous selection of aluminum profiles involves a combination of factors that directly impact performance and longevity. By following these guidelines, you can master the art of choosing high-quality aluminum profiles, ensuring your projects stand the test of time.