Introduction

While the digital landscape is teeming with information about industrial aluminum profiles, a captivating nuance remains underexplored. Why is industrial aluminum also known as assembly line aluminum profiles? Let’s delve deep and unearth the answers.

The Assembly Line: An Industrial Revolution

Assembly lines, a hallmark of industrial production methods, have been instrumental in scaling up production, curtailing costs, and infusing automation into the process. From belt assembly lines to drum assembly iterations, there are seven distinct types, each serving unique purposes.

Crafting the Backbone: Aluminum in Assembly Lines

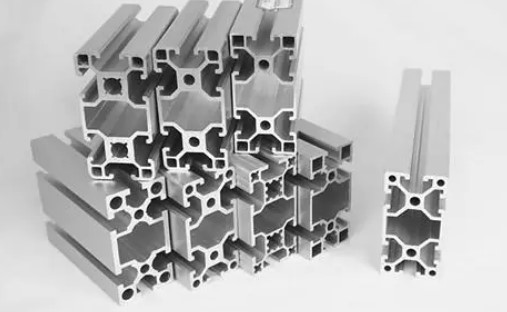

Where does aluminum fit into this narrative? Primarily, industrial aluminum profiles are pivotal in sculpting the structural backbone of assembly line equipment. Whether it’s forging workbenches, fine-tuning double speed chains, or anchoring support racks, aluminum’s versatility is unmatched.

Casting Rod Quality: A Crucial Determinant

Diving into the micro-level, the quality of casting rods plays a monumental role in the surface and extrusion formation of aluminum profiles, particularly those designed for heat dissipation. Slag inclusion, grain disparities, and segregations, among other defects, can lead to discontinuous flow, resulting in undesirable “adsorbed particles.”

Die Dynamics in Extrusion Production

In the high-pressure, high-temperature world of extrusion, the die is the unsung hero. Its inherent elastic deformation can lead to “adsorbed particles”, especially when the aluminum profile interfaces with the working strip of the mold.

Mastering the Extrusion Process

The extrusion process, with its intricacies, further influences the formation of “adsorbed particles”. Factors such as elevated temperatures and swift speeds can accentuate metal flow and mold deformation. Getting this process right can mean the difference between optimal and sub-par aluminum profiles.

Conclusion

The realm of industrial aluminum profiles is vast, with applications ranging from assembly lines to sophisticated extrusion techniques. A continuous analytical approach, combined with hands-on experience, paves the way for elevating the efficiency and output of heat dissipation fin aluminum profiles.