Hey there, aluminum enthusiasts! Rina Meng here, your trusty guide to all things aluminum. Today, we’re diving headfirst into the fascinating world of aluminum extrusion molding. Buckle up and get ready to unleash your creativity, because we’re about to explore the customization methods that will make your aluminum profiles stand out from the crowd!

Now, before we jump into the nitty-gritty of customization, let me take you on a little journey. Picture this: a workshop buzzing with activity, sparks flying, and the smell of excitement in the air. It’s like a scene straight out of a superhero movie, where ordinary aluminum transforms into extraordinary profiles. And guess what? You’re the superhero in this story, armed with the power of customization!

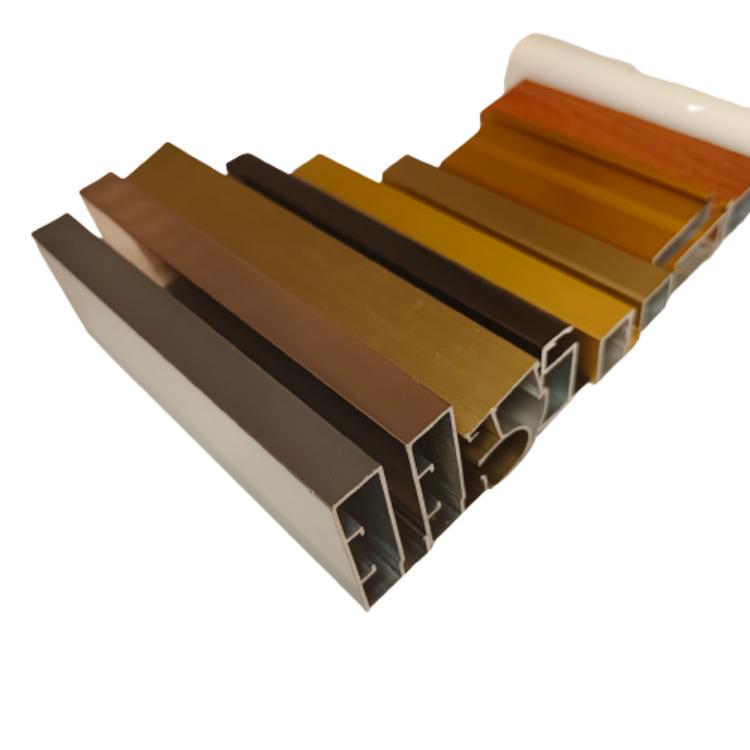

So, let’s get down to business and talk about the different methods of aluminum extrusion molding. Each method has its own unique advantages and characteristics, so you can choose the one that suits your needs and unleashes your creative genius. Let’s dive in!

- Oxidation: This method is like giving your aluminum profiles a stylish makeover. By subjecting them to the magical process of oxidation, you can achieve a silver-white surface that’s not only elegant and beautiful but also corrosion-resistant. It’s like giving your aluminum profiles a suit of armor!

- Extrusion Molding: Ah, the classic method that’s all about shaping your aluminum profiles to perfection. It’s like having your own personal aluminum profile stylist. Here’s how it works: each specification of aluminum profile has its own production mold. You simply put the aluminum into the mold and voila! It’s extruded into the exact shape and size you desire. It’s like magic, but with aluminum!

- Casting: Imagine stepping back in time to the days of blacksmithing. This method is all about channeling your inner medieval craftsman. It’s like being a part of a historical reenactment, where molten aluminum is poured into molds to create unique and intricate profiles. It’s a nod to the past with a touch of modern creativity.

- Melt Impurities: Now, let’s talk purity. The performance of aluminum profiles is directly linked to their purity. The purer the aluminum, the better the performance. So, by melting impurities away, you’re enhancing the quality of your profiles. It’s like purifying your aluminum to unleash its full potential!

- Ingredients for Hardness: We’re adding a dash of chemistry to the mix! Industrial aluminum profiles are often made from aluminum alloys like aluminum-magnesium-silicon or aluminum-zinc. These alloys work their magic by improving the hardness and load-bearing capacity of your profiles. It’s like giving your aluminum profiles a secret strength boost!

Now that you know the customization methods for aluminum extrusion molding, it’s time to unleash your creativity and let your imagination run wild. Whether you’re aiming for sleek and stylish profiles or robust and load-bearing ones, the power is in your hands!

Overall, aluminum extrusion molding is like an art form, where you can mold and shape your aluminum profiles to match your wildest dreams. So go ahead, embrace your inner artist, and create aluminum profiles that will leave everyone in awe!

Thanks for joining me on this aluminum adventure, my fellow enthusiasts. Remember, when it comes to aluminum, the possibilities are endless. So, let’s keep customizing and shaping the world, one aluminum profile at a time!

Catch you on the aluminum side!