Follow in the footsteps of Rina, take you to know more aluminum profile products

Hey there, car enthusiasts and aluminum aficionados! Rina Meng here, ready to rev up your engines and take you on a thrilling ride through the world of aluminum extrusions in the auto industry. Buckle up, because we’re about to embark on an adventure that will leave you breathless. Picture this: sleek electric vehicles, lightweight designs, and cutting-edge technology. It’s like a sci-fi movie come to life, but with a twist of aluminum!

Now, let me share a little personal anecdote to kick things off. I remember the first time I laid my eyes on an electric vehicle. It was love at first sight. The sleek lines, the futuristic design, and the promise of a greener future had me hooked. Little did I know that aluminum extrusions would play a crucial role in making these vehicles not only visually stunning but also high-performing and cost-effective. It’s like a match made in automotive heaven!

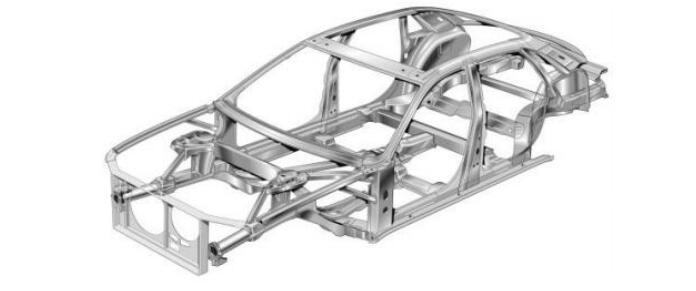

You see, automakers are turning to aluminum extrusions as a game-changer. They’re using high-strength aluminum to shed those extra pounds and make their vehicles lighter than ever before. It’s like a weight-loss journey for cars, but without the kale smoothies and endless hours at the gym. And guess what? They’re not compromising on performance or aesthetics. It’s a win-win situation, my friends!

With ever-increasing safety standards and industry regulations, the extrusion industry has stepped up its game. They’re not just supplying specific components anymore. Oh no, they’re going above and beyond to offer comprehensive solutions that meet the demands of both customers and the industry. It’s like having your own personal pit crew, ready to optimize performance and efficiency throughout the entire process. Talk about dedication!

Now, let’s talk numbers. According to the folks at Ducker Worldwide, the use of aluminum and extruded aluminum products in North American vehicles is expected to skyrocket by up to 30 percent in the next 10 years. That’s a whopping 565 pounds by 2028, representing 16 percent of the vehicle’s weight. We’re talking serious aluminum power here, my friends!

But why do auto designers and engineers have a soft spot for aluminum extrusion? Well, let me break it down for you. Aluminum extrusions allow them to play around with different aluminum alloys and profile geometries. It’s like being a kid in a candy store, but instead of candy, you’ve got an array of lightweight possibilities at your fingertips. And here’s the best part: they can tailor these extrusions to meet specific energy absorption and crash-management requirements. It’s like having a superhero suit made just for you!

But wait, there’s more! Aluminum extrusions are not just about weight savings. They also offer a plethora of solutions that increase vehicle safety. Imagine driving a car that not only looks cool but also keeps you safe. It’s like having your own personal bodyguard on wheels. And let me tell you, automakers are on the lookout for aluminum alloys that deliver excellent crash performance, high-yield strength, and reduced weight. It’s all about finding that perfect balance, my friends.

Overall, the auto industry’s love affair with aluminum extrusions is a match made in automotive heaven. It’s a journey of innovation, performance, and cost-effectiveness. With aluminum extrusions, we’re witnessing the evolution of electric vehicles and the transformation of the automotive landscape. So, fasten your seatbelts and get ready for a future where aluminum takes center stage.

Thanks for joining me on this exhilarating ride, my fellow car enthusiasts! Remember, aluminum extrusions are not just a trend; they’re a game-changer. So, embrace the aluminum revolution, and let’s drive towards a greener and more exciting future. Until next time, keep shining bright like aluminum and stay tuned for more automotive adventures. Catch you on the open road, my friends!