Introduction to Aluminium Profiles

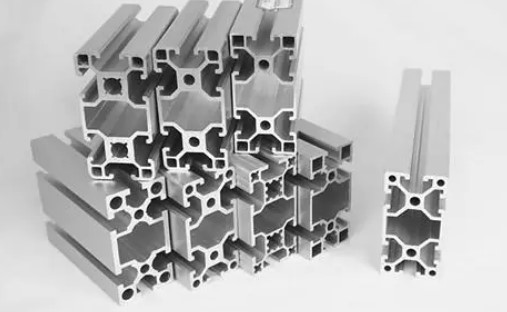

Overview of Aluminium Profiles: Aluminium profiles, essential components in various industries, offer a unique combination of strength, versatility, and lightness. Predominantly made from Aluminium 6063, these profiles are renowned for their durability and corrosion resistance. This introduction explores their significance in contemporary construction and manufacturing, highlighting their diverse applications. Aluminium profiles are not just functional elements; they represent a fusion of design and utility, serving as the backbone of numerous modern structures and mechanisms.

Importance in Modern Construction and Manufacturing: The use of aluminium profiles has transformed the landscape of construction and manufacturing. From intricate mechanical assemblies to robust industrial frameworks, these profiles are indispensable. Their lightweight nature does not compromise their strength, making them ideal for a range of applications – from small-scale DIY projects to large-scale industrial equipment. The demand for aluminium profiles continues to grow as industries seek efficient, cost-effective, and versatile materials.

Scope of the Article: In this article, we aim to delve deep into the world of aluminium profiles, examining their types, applications, and the nuances of purchasing them. Whether you are a professional in the field of mechanical engineering or a hobbyist engaged in crafting and DIY projects, this article offers valuable insights into choosing and utilizing aluminium profiles effectively.

Types and Varieties of Aluminium Profiles

B-Type and I-Type Profiles: The categorization of aluminium profiles into B-type and I-type is a crucial aspect of their application. B-type profiles are generally preferred for sturdier constructions, while I-type profiles are sought after for their flexibility and lighter weight. Each type has its unique slot profile, which is essential for connecting and assembling different components. For instance, B-type profiles with slot sizes like 8mm or 10mm are commonly used in robust structures, while I-type profiles with slots of 5mm or 6mm are ideal for lighter applications.

Slot Profiles and Their Uses: Slot profiles, a distinctive feature of aluminium profiles, enhance their adaptability. These slots allow for easy attachment of various accessories and components, making aluminium profiles incredibly versatile. They can be used in creating everything from custom workbenches and hi-fi racks to sophisticated industrial machinery. The diversity in slot profiles, including I-type slot 5 and B-type slot 6, caters to a broad spectrum of structural and functional needs.

Specialized Profiles for Specific Applications: Beyond the standard B-type and I-type, there are specialized aluminium profiles designed for specific applications. These include profiles for solar panel frames, cable conduits, and even specialized rigs for sim racing or game seats. The adaptability of aluminium profiles extends to the realm of 3D printing, where they are used for constructing stable and precise printer frames. This versatility demonstrates the profiles’ ability to meet specialized requirements across various fields.

Applications of Aluminium Profiles

Industrial and Mechanical Engineering Uses: In the realm of industrial and mechanical engineering, aluminium profiles play a pivotal role. They are extensively used in designing and constructing production equipment, machine frames, and even entire production lines. Their strength and malleability make them ideal for these applications. In industrial equipment, where durability and precision are paramount, aluminium profiles provide the necessary robustness and flexibility. The profiles are also essential in creating customized solutions for specific industrial needs, demonstrating their wide-ranging utility in this sector.

Applications in Hobby and Handicraft Projects: The use of aluminium profiles extends beyond industrial applications into the world of hobbies and DIY projects. They are a popular choice among enthusiasts for building sim racing rigs, display racks, and even custom furniture. The ease of handling and assembly makes them particularly appealing to hobbyists. Aluminium profiles enable the creation of intricate and personalized projects, from hi-fi racks to hobbyist workbenches, offering a perfect blend of strength and customization.

The Role in 3D Printing and DIY Projects: In the rapidly evolving field of 3D printing, aluminium profiles have found a significant place. They are used to build stable, precise printer frames that are crucial for high-quality 3D printing. The profiles’ rigidity ensures minimal vibration during printing, which is essential for achieving fine detail in prints. Additionally, the modularity of aluminium profiles allows for easy upgrades and modifications to 3D printers, catering to the dynamic needs of 3D printing enthusiasts and professionals alike.

Technical Specifications and Availability

Material Specifications (e.g., Aluminium 6063): Aluminium profiles are predominantly made from Aluminium 6063, a material known for its excellent mechanical properties. This alloy offers a balance of strength, corrosion resistance, and formability, making it ideal for profiles used in various applications. Aluminium 6063’s ability to withstand harsh environments while maintaining its structural integrity is a key factor in its widespread use. The material’s composition also allows for efficient anodizing, further enhancing its durability and aesthetic appeal.

Size and Dimension Variations: The versatility of aluminium profiles is also evident in their size and dimension variations. From compact profiles of 20×20 mm to larger dimensions like 40×80 mm or even 45×180 mm, the range available caters to a multitude of structural requirements. This diversity in size and shape allows for a broad spectrum of applications, from delicate precision parts to large, sturdy structures. The ability to customize these dimensions to specific needs adds another layer of utility, making aluminium profiles a go-to choice for many projects.

Availability and Customization Options: Aluminium profiles are readily available through various channels, including specialized online stores like Motedis and physical outlets. These profiles can be purchased in standard lengths or cut to specific dimensions, offering a high degree of customization. Suppliers often provide additional services like drilling, milling, and even the assembly of components, making it easier for customers to obtain profiles tailored to their specific project requirements. The availability of these customization options underscores the profiles’ adaptability and user-friendliness in both professional and hobbyist settings.

Purchasing Aluminium Profiles

Factors to Consider When Buying: When purchasing aluminium profiles, several factors need to be considered. The type of profile (B-type or I-type), the size and dimensions, and the specific application are crucial in making the right choice. It is also important to consider the quality of the aluminium, ensuring that it meets the required strength and durability standards. Buyers should assess the compatibility of profiles with other components and accessories they plan to use, ensuring seamless integration in their projects.

Pricing and Tax Considerations: The cost of aluminium profiles can vary widely based on type, size, and customization. It is essential to factor in additional costs such as taxes and shipping, especially when ordering from online stores. For instance, the price of a 40×40 L I-type slot 8 profile can differ significantly from a 30×120 B-type slot 8 profile. Being aware of these pricing nuances can help in budgeting and planning for projects. Additionally, understanding the tax implications in your region can prevent unexpected expenses.

Where to Purchase: Online Stores and Physical Outlets: Aluminium profiles can be sourced from various outlets. Online stores like Motedis offer a wide range of profiles with the convenience of customization and direct shipping. Physical stores, on the other hand, provide the advantage of firsthand inspection and immediate availability. Depending on the project’s urgency and specific requirements, buyers can choose the most suitable purchasing avenue. It’s advisable to compare prices, availability, and services offered by different suppliers to make an informed decision.

Conclusion

Recap of Aluminium Profiles’ Significance: The integral role of aluminium profiles in modern construction, manufacturing, and DIY projects cannot be overstated. Their adaptability, strength, and ease of use make them a preferred choice in a multitude of applications. As we have explored, the variety of profiles and their applications are vast, catering to both industrial and personal project needs.

Future Trends in Aluminium Profile Usage: The future of aluminium profiles looks promising, with ongoing innovations and expanding applications. As industries continue to evolve, the demand for versatile, durable, and cost-effective materials like aluminium profiles is likely to increase. This trend suggests a bright future for aluminium profiles, with new uses and applications emerging in various sectors.

Final Thoughts and Recommendations: Whether you’re a professional engineer, a hobbyist, or someone in between, understanding the nuances of aluminium profiles is crucial for your projects. This comprehensive guide aims to equip you with the knowledge needed to make informed decisions when working with aluminium profiles. Remember, the right profile can be the key to the success of your project, so choose wisely!

FAQs

Q1: What are the main types of aluminium profiles?

A1: The main types are B-type and I-type, each suited for different applications in construction and manufacturing.

Q2: Can aluminium profiles be customized?

A2: Yes, most suppliers offer customization options, including cutting profiles to specific lengths and dimensions.

Q3: What are common applications of aluminium profiles in DIY projects?

A3: They are widely used in building custom 3D printers, gaming rigs, and various other handicraft projects.

Q4: What factors should be considered when purchasing aluminium profiles?

A4: Consider the type, size, application requirements, quality, and durability when making a purchase.

Q5: Are aluminium profiles suitable for use in industrial settings?

A5: Yes, they are commonly used in industrial and mechanical engineering for production lines, equipment frames, and other components.