Introduction

Anodized aluminum films are a marvel in the realm of materials science, widely used across diverse industries. This article explores their intricate two-layer structure, comprising a porous outer layer and a dense inner barrier layer, and their unique properties.

Understanding the Anodized Film Structure

The anodized film is distinct in its dual-layer composition. The outer layer is thick and porous, while the inner barrier layer is dense, possessing dielectric properties essential for the film’s functionality.

Importance of Timely Dyeing Post-Anodization

Post-anodization, timely dyeing is crucial to maintain the film’s integrity. Delay can lead to shrinkage and contamination, affecting the film’s quality. If immediate dyeing is not possible, storing the workpiece in clean water is advisable.

Microscopic View of Anodized Films

Under an electron microscope, anodized films reveal tubular pores organized in a honeycomb hexagonal pattern, forming countless unit cells. This microscopic structure plays a key role in the film’s properties.

Composition and Characteristics of the Barrier Layer

The barrier layer, primarily composed of anhydrous anodized aluminum, is thin yet dense. It effectively prevents current passage, contributing to the film’s hardness and protective qualities.

The Porous Outer Layer: Composition and Significance

Comprising mainly amorphous anodic aluminum oxide, the porous outer layer includes cations from the electrolyte, impacting its overall characteristics. This layer’s thickness and porosity are pivotal in determining the film’s properties.

Factors Influencing Anodized Film Properties

The anodizing conditions significantly influence the porous outer layer’s thickness and porosity, thus affecting the film’s overall attributes. These factors are crucial in ensuring the film meets specific application requirements.

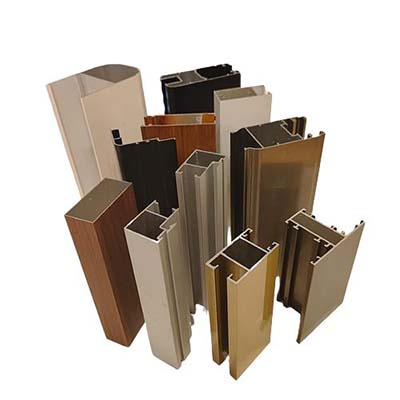

Applications of Anodized Aluminum Films

Anodized aluminum films find applications in various fields, from aerospace to consumer electronics, owing to their unique properties. Their structure makes them ideal for specific uses where durability and electrical insulation are paramount.

Conclusion

Anodized aluminum films, with their unique structure and properties, play a vital role in modern industry. Understanding their composition and handling them properly is essential to harness their full potential in various applications.