Follow Rina to show you more information about aluminum profiles

Hey there, fellow aluminum enthusiasts! Rina Meng here, your friendly neighborhood aluminum profile expert. Today, I want to delve into the captivating world of powder spraying and its remarkable application in the surface treatment of aluminum profiles. Get ready for a rollercoaster ride of information and a sprinkle of humor along the way!

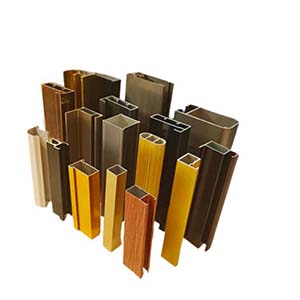

Let’s kick things off with a personal anecdote. Picture this: I was strolling through a modern building, marveling at its sleek and stylish interior. The secret behind its captivating allure? Powder-sprayed aluminum profiles! The surfaces gleamed with vibrant colors and a flawless finish that made my heart skip a beat. Intrigued by this visual feast, I dived headfirst into the world of powder spraying, and boy, was I in for a treat!

Now, before we dive deeper, let’s talk about the three main surface treatment methods for aluminum profiles: anodizing, electrophoretic coating, and powder spraying. Each method has its own unique advantages, but today, our spotlight shines on powder spraying. So, buckle up and let’s explore its remarkable characteristics!

First things first, powder spraying offers a relatively simple process that has undergone significant improvements in recent years. Thanks to advancements in automatic equipment and microcomputer control, the process has become more streamlined and less daunting. Say goodbye to complex operations and hello to a smoother, more efficient workflow. It’s like having a personal assistant that takes care of all the nitty-gritty details, leaving you with more time to sip your favorite beverage!

One of the standout features of powder spraying is its impressive yield rate. With the right measures in place, the production of defective products can be kept to a minimum. It’s like having a secret recipe for success, ensuring that your aluminum profiles come out looking fabulous every single time. Who doesn’t love a high success rate and a little sprinkle of magic?

Now, let’s talk energy consumption. In comparison to other surface treatment methods like anodizing and electrophoretic coating, powder spraying takes the cake when it comes to reducing energy consumption. The traditional processes can be quite thirsty when it comes to water and electricity. But with powder spraying, those numbers take a nosedive. You’ll save on power bills and reduce your environmental footprint. It’s a win-win situation, my friends!

Speaking of the environment, powder spraying also boasts a reduced impact on water and air pollution. Say goodbye to caustic soda and sulfuric acid, and hello to a cleaner, greener future. By eliminating the use of these harmful substances, aluminum profiles treated with powder spraying become more environmentally friendly. It’s like giving Mother Nature a warm, fuzzy hug!