The Superiority of Aluminum Alloy Heat Sinks in Modern Applications

Heat sinks play a critical role in maintaining the efficiency and longevity of various electronic and mechanical systems by dissipating heat generated during operation. Among the materials used for heat sinks, aluminum alloy stands out as a preferred choice, particularly in the electrical industry, due to its excellent balance of cost and performance.

Materials Used in Heat Sinks

Traditionally, copper and aluminum alloy are the two primary materials used for heat sinks. Copper, known for its superior thermal conductivity, has been widely used. However, it has several drawbacks: it is expensive, difficult to process, heavy, has a small heat capacity, and is prone to oxidation. These disadvantages have led to a decline in its use for heat sinks.

On the other hand, aluminum alloy offers a compelling alternative. While its thermal conductivity is lower than that of copper, aluminum alloy is significantly cheaper, easier to process, lighter in weight, and boasts a higher heat capacity. This makes it an ideal material for heat sinks, especially when cost-effectiveness and ease of manufacturing are important considerations.

Properties and Advantages of Aluminum Alloy Heat Sinks

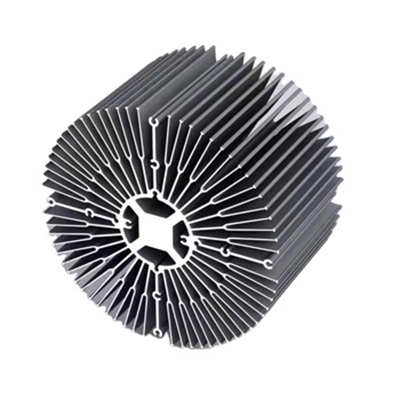

Aluminum alloy heat sinks are not only economically advantageous but also highly efficient in heat dissipation. They offer a good balance of thermal conductivity and weight, making them suitable for a wide range of applications. Additionally, the energy-saving benefits of aluminum alloy heat sinks are notable. They enhance the overall efficiency of systems by reducing the need for additional cooling mechanisms.

The surface of aluminum alloy heat sinks forms a protective oxide layer after oxidation, which significantly increases their corrosion resistance and wear resistance. This protective film ensures that the heat sinks remain functional and aesthetically pleasing over time. Moreover, the lightweight nature of aluminum alloy makes it easier to handle and install, further enhancing its appeal.

Applications of Aluminum Alloy Heat Sinks

The superior performance of aluminum alloy heat sinks has led to their widespread use across various industries. In the machinery sector, these heat sinks ensure that equipment operates smoothly by effectively managing heat dissipation. In the automotive industry, aluminum alloy heat sinks are crucial in maintaining the performance and reliability of various components, from engines to electronic systems.

Household appliances, such as refrigerators and air conditioners, also benefit from the use of aluminum alloy heat sinks. Their efficiency and durability make them ideal for maintaining optimal performance in these appliances. Beyond these, aluminum alloy heat sinks are used in a multitude of other industrial applications where efficient heat management is essential.

Enhancements and Innovations in Aluminum Alloy Heat Sinks

To further enhance the performance of aluminum alloy heat sinks, some designs incorporate embedded copper plates. This hybrid approach leverages the high thermal conductivity of copper while maintaining the cost and weight benefits of aluminum alloy. The protective oxide layer on aluminum not only enhances corrosion resistance but also improves the overall durability of the heat sinks.

Design innovations have also played a role in improving both the functionality and appearance of aluminum alloy heat sinks. Aesthetic improvements ensure that these components not only perform well but also fit seamlessly into the design of modern devices and systems.

Conclusion

Aluminum alloy heat sinks offer an exceptional combination of cost-effectiveness, efficiency, and durability, making them the material of choice for a wide range of applications. As technology continues to advance, the use of aluminum alloy in heat sinks is likely to grow, driven by ongoing innovations and an increasing emphasis on energy efficiency and sustainability. The future of heat dissipation technology looks promising, with aluminum alloy at the forefront of this evolution.