Introduction to Aluminium Extrusion

Definition and Overview

Aluminium extrusion, a cornerstone in modern manufacturing, is a fascinating process that transforms aluminium alloy into diverse and complex profiles. This technique has revolutionized the way we use aluminium, offering unparalleled flexibility in design and application. The process involves heating the aluminium to a pliable state and then forcing it through a die to create the desired shape. This introduction will explore the fundamental aspects of aluminium extrusion, underscoring its significance in today’s industrial landscape.

The Evolution of Aluminium Extrusion

The history of aluminium extrusion is a tale of innovation and evolution. Originating in the early 19th century, the process has undergone significant advancements, paralleling the technological growth of the industrial world. From rudimentary methods to highly sophisticated techniques, aluminium extrusion has evolved to meet the increasing demands of precision and complexity in various sectors. This section delves into this historical journey, highlighting key milestones that have shaped the aluminium extrusion process we know today.

Importance in Modern Manufacturing

Today, aluminium extrusion plays a pivotal role in modern manufacturing, owing to its versatility and efficiency. It enables the production of shapes that are both structurally sound and aesthetically pleasing, meeting diverse industry requirements. The significance of aluminium extrusion extends beyond its technical capabilities; it also contributes to economic growth and innovation in various fields, from construction to automotive industries. This section discusses the impact of aluminium extrusion on modern manufacturing and its contribution to advancing technology.

The Aluminium Extrusion Process

Step-by-Step Guide

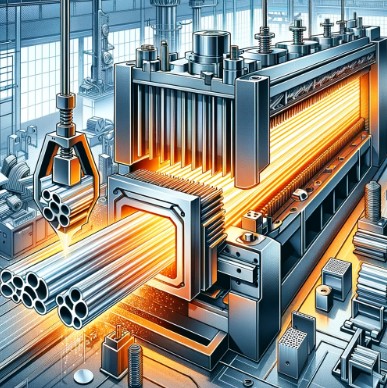

The aluminium extrusion process involves several critical steps to transform raw aluminium into functional profiles. Starting with the heating of aluminium billets, the process moves to the extrusion through dies and cooling of extruded profiles. Each step is meticulously controlled to ensure the integrity and quality of the final product. This detailed exploration offers insight into the technicalities of the process, illustrating how aluminium is shaped into intricate profiles used across various industries.

Heat Treatment and Mechanical Properties

Post-extrusion, aluminium profiles often undergo heat treatment, significantly enhancing their mechanical properties. This treatment alters the microstructure of aluminium, improving its strength and durability. For instance, heat-treated 6061 aluminium exhibits a remarkable increase in tensile strength, vital for applications requiring robust materials. This section explains the science behind heat treatment and its effect on aluminium’s mechanical properties, underlining its importance in the extrusion process.

Examples of Aluminium Extrusion Products

Aluminium extrusion is behind many everyday items and industrial components, from frames in 3D printers to structural elements in buildings. This versatility stems from the process’s ability to create varied cross-sectional profiles. The diversity of products made through aluminium extrusion showcases the process’s adaptability and relevance across different sectors. This section provides examples of aluminium extrusion products, illustrating the process’s real-world applications.

Enhancing Aluminium Profiles

Surface Finishing Techniques

Following extrusion, aluminium profiles can be further enhanced through various surface finishing techniques. These processes not only improve the aesthetic appeal but also augment the material’s resistance to corrosion and wear. Techniques like anodization, painting, and powder coating are common methods used to protect and beautify aluminium profiles. This section explores these finishing techniques, explaining how they contribute to the longevity and functionality of aluminium extrusion products.

Benefits of Anodization and Coatings

Anodization, a popular finishing technique for aluminium extrusions, offers significant benefits. It strengthens the naturally occurring oxide layer, thereby bolstering the metal’s resistance to corrosion and wear. Additionally, anodized aluminium can be dyed in various colors, enhancing its visual appeal. Other coatings, such as powder coating, provide similar protective and aesthetic enhancements. This section delves into the advantages of anodization and other coatings, demonstrating their role in extending the lifespan and versatility of aluminium extrusions.

Customization through Fabrication

Aluminium extrusion products can be customized through various fabrication techniques to meet specific project requirements. Operations like drilling, machining, and cutting allow for precise dimensions and configurations. This customization capability is particularly beneficial in sectors requiring tailor-made solutions, such as bespoke machinery parts or architectural elements. This section highlights the flexibility of aluminium extrusion in fabrication, showcasing its adaptability to diverse and specific applications.

Applications of Aluminium Extrusion in Various Industries

Usage in 3D Printing and CNC Machines

Aluminium extrusion finds extensive application in the realms of 3D printing and CNC machining. Its strength, malleability, and precision make it an ideal material for constructing frames and components of these machines. The ability to create complex profiles with aluminium extrusion caters perfectly to the intricate and customized requirements of 3D printing and CNC technology. This section examines how aluminium extrusion contributes to advancements in these cutting-edge fields.

Role in Construction and Infrastructure

In the construction and infrastructure sectors, aluminium extrusion plays a crucial role. Its properties, such as lightweight and corrosion resistance, make it a preferred choice for structural components in buildings, bridges, and transportation systems. This section explores the application of aluminium extrusion in construction, highlighting its benefits and the transformative impact it has on building and infrastructure projects.

Innovative Applications in Other Sectors

Beyond the traditional domains, aluminium extrusion is making inroads into innovative sectors like renewable energy and aerospace. Its adaptability and strength-to-weight ratio open up new possibilities in these industries, where efficiency and performance are paramount. This section delves into these novel applications, showcasing the versatility and potential of aluminium extrusion in pushing the boundaries of modern technology.

Conclusion

Future Trends in Aluminium Extrusion

Looking ahead, aluminium extrusion is poised to play an even more significant role in technological and industrial advancements. As demand for lightweight, strong, and versatile materials increases, the aluminium extrusion process will continue to evolve, meeting these emerging needs. This concluding section discusses future trends and potential innovations in aluminium extrusion, emphasizing its ongoing relevance in a rapidly changing world.

Choosing the Right Aluminium Extrusion for Your Project

Selecting the appropriate aluminium extrusion is crucial for any project’s success. Understanding the specific requirements of a project, from strength to aesthetics, guides the choice of alloy and finishing techniques. This section provides guidance on making informed decisions when choosing aluminium extrusions, ensuring the best fit for diverse applications.

Final Thoughts and Further Reading

In conclusion, aluminium extrusion is a versatile and essential process in modern manufacturing. Its ability to produce varied and complex profiles caters to a wide range of industries and applications. This article serves as an introduction to the world of aluminium extrusion, inviting readers to explore further and appreciate the process’s depth and breadth. Additional resources and reading materials are suggested for those interested in delving deeper into this fascinating subject.

FAQ Generation

Frequently Asked Questions About Aluminium Extrusion

Q1: What is Aluminium Extrusion?

A1: Aluminium extrusion is a manufacturing process where aluminium alloy is heated and forced through a die to create profiles with specific shapes. This process allows for the production of complex and versatile aluminium shapes used in various industries.

Q2: Why is Aluminium Extrusion Important in Manufacturing?

A2: Aluminium extrusion is crucial in manufacturing due to its ability to create diverse and complex shapes with high precision. It contributes to the design flexibility, structural integrity, and aesthetic appeal of products in industries like construction, automotive, and 3D printing.

Q3: How Does Heat Treatment Enhance Aluminium Extrusion Profiles?

A3: Heat treatment enhances the mechanical properties of aluminium extrusion profiles by altering their microstructure. It increases the material’s tensile strength and durability, making it suitable for applications requiring robust and long-lasting components.

Q4: What are the Common Surface Finishing Techniques for Aluminium Extrusions?

A4: Common surface finishing techniques for aluminium extrusions include anodization, painting, powder coating, and sandblasting. These processes improve the appearance, corrosion resistance, and wear resistance of the aluminium profiles.

Q5: Can Aluminium Extrusion be Customized for Specific Applications?

A5: Yes, aluminium extrusion can be customized through various fabrication techniques like drilling, machining, and cutting. This customization allows for precise dimensions and configurations, making aluminium extrusion adaptable to a wide range of specific applications.