Understanding the Aluminum Profile Extrusion Process: A Step-by-Step Guide

Aluminum and aluminum alloy profiles are essential materials widely used in various industries, including construction, transportation, electronics, and aerospace. Their unique properties, such as corrosion resistance, lightweight, and high strength, make them ideal for numerous applications. In recent years, the demand for miniaturized and lightweight components, particularly in the automotive industry, has led to a rapid increase in the use of aluminum extrusion products like heat exchanger tubes and hollow profiles. Let’s delve into the aluminum profile extrusion production process to understand how these versatile profiles are created.

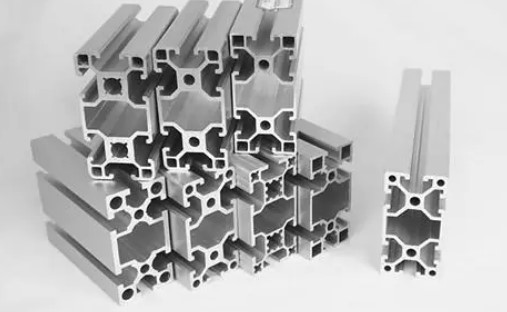

Overview of Aluminum Profile Extrusion

Aluminum profile extrusion is a manufacturing process that transforms aluminum bars into specific shapes and profiles through a die. This process is crucial for producing high-quality, precise aluminum profiles that meet the stringent requirements of various applications. The benefits of aluminum extrusion include the ability to create complex shapes, enhanced material strength, and versatility in application.

Detailed Steps in the Aluminum Profile Extrusion Process

Aluminum Bar Flattening The first step involves spreading the prepared aluminum bars flat on a rack. It’s important to leave a certain gap between the bars and avoid stacking them to facilitate easy handling by the extruder.

Aluminum Bar Heating Heating the aluminum bars requires precise temperature control. The bars are heated from room temperature until they reach 480℃ over approximately 3.5 hours. Maintaining the correct temperature is critical, as deviations can affect the hardness and quality of the finished product.

Mold Heating The molds used in the extrusion process are heated to the same temperature as the aluminum bars, 480℃, to ensure uniformity. This step involves heating and maintaining the temperature to prepare the mold for extrusion.

Mold Preparation Once the mold and aluminum rod are heated and maintained at the correct temperature, the mold is placed on the extruder seat, ready for the extrusion process.

Aluminum Rod Sent to Raw Material Outlet The heated and prepared aluminum rod is then placed into the raw material inlet of the extruder, set to begin the extrusion process.

Aluminum Profile Rod Extrusion During this step, the aluminum profile is extruded through the die, emerging from the outlet in the desired shape. This stage requires careful monitoring to ensure the profile meets the required specifications.

Aluminum Profile Tractor The extruded aluminum profile is pulled by a tractor, which also helps determine the length for cutting. This step ensures the profiles are of uniform length and ready for further processing.

Aluminum Profile Straightening After cutting, the aluminum profiles are sent to the straightening table. Straightening is essential to ensure the profiles maintain their shape and are free from distortions, making them suitable for final applications.

Aging Treatment The straightened aluminum profiles are then transported to the aging area, where they undergo aging treatment in a furnace. The temperature is maintained at 200℃ for about 2 hours to enhance the material properties.

Natural Cooling After aging, the profiles are cooled either naturally or using a cold air blower. Proper cooling is vital to achieving the desired mechanical properties and ensuring the final product meets quality standards.

Applications of Extruded Aluminum Profiles

The versatility of extruded aluminum profiles makes them suitable for a wide range of applications:

Construction: Used in window frames, door frames, and structural components due to their lightweight and high strength.

Transportation: Essential in automotive parts, train components, and aerospace structures for their ability to reduce weight and improve efficiency.

Electronics: Utilized in heat exchangers, housings, and connectors, benefiting from aluminum’s excellent thermal conductivity and strength.

Conclusion

The aluminum profile extrusion process is a meticulous and precise method that transforms aluminum bars into versatile profiles used across various industries. Each step, from flattening and heating to extrusion and cooling, plays a crucial role in ensuring the high quality and performance of the final product. As technology advances, the aluminum extrusion industry continues to innovate, meeting the evolving demands of modern applications and driving future developments in material science.