Introduction

In the radiator industry, aluminum alloys play a crucial role, particularly in electronic products. They not only protect internal parts but also aid in heat conduction and dissipation. However, there’s a common confusion between “aluminum profile radiators” and “radiator aluminum profiles.” Though they sound similar, they are distinct concepts. Understanding these differences is essential to avoid mistakes when looking for suppliers or services.

Aluminum in Radiator Manufacturing

Aluminum is prized for its excellent thermal conductivity, lightweight nature, and resistance to corrosion, making it an ideal material for radiators. In electronics, aluminum radiators are used to efficiently dissipate heat, ensuring the longevity and performance of the devices.

What is Radiator Aluminum Profile?

Radiator aluminum profile refers to the raw material used in making radiators. This material is created by melting aluminum alloy and die-casting it into specific shapes. At this stage, the aluminum profile has not undergone any further processing. It has a rough surface, lacks aesthetic appeal, and has poor heat dissipation performance. Unfortunately, many people mistake these raw profiles for finished radiators, leading to potential scams and misunderstandings.

What is an Aluminum Profile Radiator?

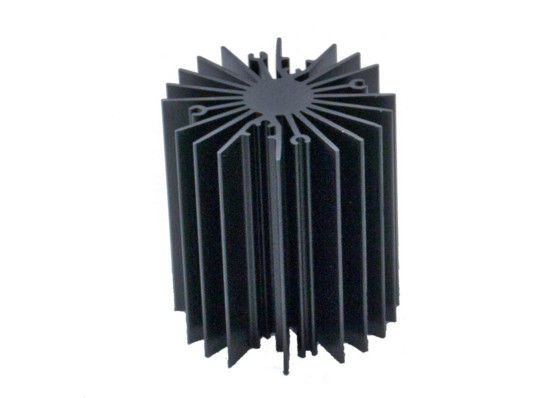

An aluminum profile radiator, on the other hand, is a finished product processed from aluminum profiles. Radiator manufacturers customize these profiles using various techniques such as sandblasting, wire drawing, polishing, anodizing, laser engraving, silk screen printing, and CNC processing. The result is a radiator that meets specific requirements in terms of size, appearance, and performance. These radiators are not only aesthetically pleasing but also offer excellent heat dissipation and stable structures, making them ideal for specific applications.

Key Differences Between Aluminum Profile Radiators and Radiator Aluminum Profiles

Raw Material vs. Finished Product: Radiator aluminum profiles are raw materials, whereas aluminum profile radiators are fully processed and finished products.

Processing and Customization: Aluminum profile radiators undergo extensive processing and can be customized to meet specific needs, unlike the raw radiator aluminum profiles.

Practical Applications and Usability: Aluminum profile radiators are ready for installation and use in electronic products, offering superior performance and aesthetic appeal. In contrast, radiator aluminum profiles require further processing before they can be used.

How to Distinguish Between the Two

To avoid confusion and potential scams, it’s crucial to distinguish between radiator aluminum profiles and aluminum profile radiators. Look for the following:

Radiator Aluminum Profiles: These will have a rough, unfinished surface and will not be ready for immediate use.

Aluminum Profile Radiators: These are fully finished, often with smooth surfaces, customized designs, and enhanced performance features.

Using the correct terminology when searching for products or services will help you find the right suppliers and avoid unnecessary trouble.

Conclusion

Understanding the difference between aluminum profile radiators and radiator aluminum profiles is essential for anyone involved in the radiator industry. By clearly distinguishing between these two terms, you can avoid scams, find the exact products you need, and ensure that your electronic devices are equipped with high-quality, efficient radiators. Always choose reputable companies that offer precise customization to meet your specific requirements.