Follow Rina to show you more information about aluminum profiles

Hey there, aluminum aficionados! Rina Meng here, ready to electrify your world with some electrifying knowledge about electrophoretic coating on aluminum profiles. Trust me, folks, this coating is a total game-changer, and today, I’m going to spill the beans on its mind-blowing effects. Buckle up and get ready for an electrifying adventure!

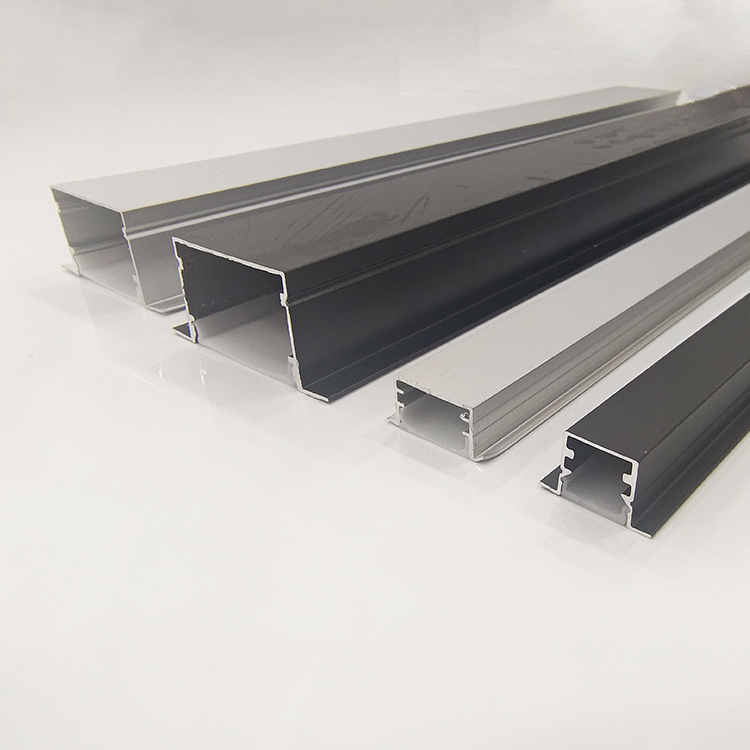

Let me kick things off with a personal story. Picture this: I’m strolling through a factory, surrounded by aluminum profiles in all their metallic glory. Suddenly, I stumble upon a group of profiles that have undergone a magical transformation. They’re coated with an enchanting electrophoretic coating, and boy, do they look stunning! It’s like they’ve put on a shiny armor that screams both style and substance.

Now, let’s dive into the nitty-gritty of why electrophoretic coating is a total game-changer for aluminum profiles. Brace yourselves, my friends, because the advantages are as significant as finding a unicorn in a haystack!

Advantage 1: Total Control over Coating Thickness

One of the coolest things about electrophoretic coating is that you can control the thickness of the coating film as if you were a master artist wielding a paintbrush. It’s like having the power to decide the perfect amount of coating for your profiles. In most cases, the thickness is controlled at around 7 to 12 microns. It’s like painting your aluminum profiles with precision and finesse!

Advantage 2: Strict Process Requirements for Improved Yield

When it comes to electrophoretic coating, the treatment process requirements are as strict as a teacher monitoring a rowdy classroom. But guess what? That strictness works in our favor! It actually helps improve the yield of industrial aluminum profiles. It’s like having a strict coach who pushes you to reach your full potential. You might grumble at first, but in the end, you’ll thank them for making you shine!

Advantage 3: Aesthetics and Durability in Perfect Harmony

Prepare to have your mind blown, my friends. The quality of the electrophoretic coating film is top-notch. The secret ingredient? Acrylic resin mixed with amino resin, creating a solid coating that’s not only visually stunning but also highly resistant to corrosion and erosion. It’s like having a superhero shield that protects your aluminum profiles from the forces of nature. Plus, the resin’s transparency beautifully highlights the metal texture of the profiles. Talk about a double whammy of aesthetics and durability!

Advantage 4: High Application Efficiency

Efficiency is the name of the game, folks! Thanks to the low viscosity of the paint used in electrophoretic coating, there’s less wastage of aluminum profile products. And get this: the electrophoretic workpieces can be washed with water, making the whole process eco-friendly. It’s like being a savvy environmentalist while still rocking the aluminum game. Plus, with the help of recycling equipment, the paint utilization efficiency reaches more than 95%. Now that’s what I call efficiency on steroids!

Advantage 5: The Automation Revolution

Ready for a revolution, my friends? Electrophoretic coating makes automated production a piece of cake. Picture this: aluminum profiles being coated in a water-based electrophoretic tank, just like anodizing and electrolytic dyeing. The processing time is short, making it a breeze to complete the assembly line work. It’s like having a well-oiled machine that works tirelessly to bring your aluminum dreams to life. Automation for the win!

Advantage 6: Time and Manpower Savings

Let’s talk about saving precious resources, shall we? Unlike the general electrolytic dyeing process that requires sealing small holes, electrophoretic coating skips that step altogether. It’s like skipping the long line at a theme park and going straight to the thrilling rides! By eliminating the need for sealing small holes, we save time and manpower.