Rina takes you on today’s journey together

Hey there, aluminum aficionados! Rina Meng here, ready to unravel the mystery behind two types of aluminum pipes—seamless and combined die extruded. Get your popcorn ready, because it’s time for the ultimate showdown!

Let’s kick things off with a little background. Most aluminum tubes you find on the market are made using the conventional combined die welding and extrusion processes. Now, these processes can’t completely dodge those pesky welding lines, especially after oxidation. And you know what happens when things get oxidized? Dark lines start creeping in, like uninvited guests at a party. Not cool, right?

So, what’s the deal with combined die extrusion? Well, it involves short round rods, high temperatures, and slow-speed extrusion. It’s like a delicate dance, where the “three temperatures” must be perfectly controlled. Picture this: clean aluminum rods, a squeaky-clean extrusion barrel, and a pristine mold. It’s all about keeping things spick and span! And let’s not forget about aging time and temperature. They’re like the secret ingredients that determine the thickness of the tube wall and the diameter of the pipe. It’s all about finding that sweet spot, my friends!

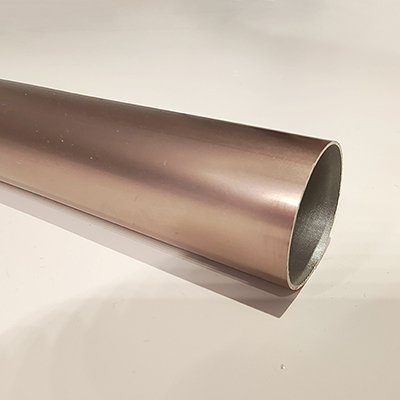

Now, let’s shift our attention to seamless aluminum pipes. These babies are produced using the perforation extrusion method. And boy, do they have some impressive qualities! They’re lightweight, easy to process, and boast high mechanical strength. It’s like having a superhero in the world of pipes! But here’s the catch—producing seamless aluminum pipes requires precision and strict production process requirements. We’re talking about a high-stakes game, folks!

During the production of seamless aluminum pipes, there are a few things that need to be carefully considered. Trust me, I’ve been through the wringer with these pipes, and I’ve got some insider knowledge to share. First things first, the aluminum oxide hydrate that pops up during production needs to be continuously extruded. It’s like a bubbly party happening inside the pipe! To prevent those pesky blisters, the round aluminum rod used for extrusion must be crack-free and stored far away from humid environments. We don’t want any moisture crashing this aluminum extravaganza!

But wait, there’s more! The cleaning solution used in the process should have a sodium hydroxide content of around 30%. It’s like finding the perfect balance between clean and shiny. And let’s not forget about the aluminum ion content in the cleaning solution. It’s all about keeping things in check and maintaining the quality of those seamless pipes.

Now, let’s get down to the nitty-gritty. What’s the difference between these two contenders? Well, combined die extruded aluminum pipes have those pesky welding lines, while seamless aluminum pipes are all about that smooth, line-free experience. It’s like the difference between a bumpy road and a smooth highway. Both have their merits, but it ultimately comes down to personal preference and the specific requirements of your project.

Overall, the world of aluminum pipes is a fascinating one. It’s a world where welding lines battle against seamless perfection, where temperatures and pressures dance together, and where precision is key. So, my aluminum-loving friends, choose your side wisely and let the pipes do the talking!

And with that, I bid you adieu. Thanks for joining me on this aluminum adventure! Remember, when it comes to pipes, whether they’re seamless or combined die extruded, always keep your dreams flowing and your projects piping hot!